|

Heanjia Super-metals Co., Ltd.

|

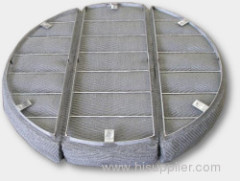

Monel Mist Eliminator Sea Water Desalinization

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Monel Mist Eliminator: corrosion resisting: resistant to sea water and steam at high temperatures, resistant to salt and caustic solution

Monel Mist Eliminator

Monel Mist Eliminators include two kinds: Monel 400 Mist Eliminator and Monel K500 Mist Eliminator.

Monel 400 Mist Eliminator is corrosion resisting, such as resistant to sea water and steam at high temperatures, resistant to salt and caustic solutions. It also has high strength. Monel 400 Mist Eliminator has low corrosion rate in flowing brackish or seawater while performing excellent resistance to stress-corrosion cracking in most freshwaters. This mesh's good resistance to a variety of corrosive conditions contributes to the wide application in marine and other non-oxidizing chloride solutions. Monel 400 Mist Eliminator is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. However, its high copper content, make alloy 400 can be rapidly attacked by nitric acid and ammonia systems.

Monel 400 Mist Eliminator also has good Adaptability to wide range of application temperature. It maintains good mechanical properties at subzero temperatures, as well as in temperatures up to 1000° F, The melting point is 2370-2460° F.

Monel K500 Mist Eliminator combines the excellent corrosion resistance of Monel 400 Mist Eliminator with the added advantage of greater strength and hardness. Alloy K-500 Mist Eliminator has approximately three times the yield strength and double the tensile strength when compared with alloy 400. When in the age-hardened condition, Monel K-500 Mist Eliminator has a greater tendency toward stress-corrosion cracking in some conditions than Monel 400 alloy Mesh. The strength of this nickel Copper alloy is maintained to 1200° F but stays ductile and tough down to temperatures of 400° F. Its melting range is 2400-2460° F. Nickel alloy K-500 Mist Eliminator has a greater tendency toward stress-corrosion cracking in some environments. Monel K-500 Mist Eliminator is resistant to a sour-gas environment. The combined Characteristics of very low corrosion rates in high-velocity sear water and high strength make alloy K-500 Mist Eliminator particularly suitable for marine service. In stagnant or slow-moving sea water, fouling may occur followed by pitting but this pitting slows down after a fairly rapid initial attack.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Eliminator

Sea Water Pump

Sea Water Scooter

Mist Water Sprayer

Static Eliminator

Monel Sheets

More>>