|

Heanjia Super-metals Co., Ltd.

|

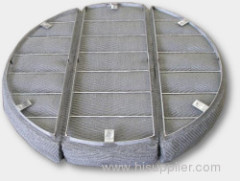

Monel 400 Demister Alloy 400

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Monel 400 Demister: corrosion resisting: resistant to sea water and steam at high temperatures, resistant to salt and caustic solutions

Monel 400 Demister

Monel 400 Demister is corrosion resisting, such as resistant to sea water and steam at high temperatures, resistant to salt and caustic solutions. It also has high strength. Monel 400 Demister has low corrosion rate in flowing brackish or seawater while performing excellent resistance to stress-corrosion cracking in most freshwaters. This mesh's good resistance to a variety of corrosive conditions contributes to the wide application in marine and other non-oxidizing chloride solutions. Monel 400 Demister is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. However, its high copper content, make alloy 400 can be rapidly attacked by nitric acid and ammonia systems.

Monel 400 Demister also has good Adaptability to wide range of application temperature. It maintains good mechanical properties at subzero temperatures, as well as in temperatures up to 1000° F, The melting point is 2370-2460° F.

Monel 400 Demister are porous blankets of monel wire knitted mesh, designed and constructed for the efficient, economical removal of entrained liquid droplets from vapor streams. Mesh Pads can be fabricated in any required size and shape and may be installed in new or existing process vessels. Monel 400 Demister consists of a pad of knitted monel wire mesh usually sandwiched between grids for mechanical support. Except for units less than about 600mm diameter, they are normally split into sections of between 300 to 400mm wide to facilitate installation through a normal vessel manway. The pads are cut slightly oversize to ensure a snug fit and thus eliminate any possible vapor by-pass either between sections or between pad and vessel wall (or shroud). Each monel mesh pad is formed from crimped layers of fabric knitted from monofilament with the direction of the crimp rotated 90 degrees in each adjacent layer to provide a uniform voidage together with a high ratio of filament surface per unit volume of pad. Standard support grids consist of a framework of 25mm x 3mm thick flat bar fixed to a grid consisting of 6mm rods usually spaced on 150mm centers to retain the mesh with minimum obstruction of the face of the pad. The top and bottom grids are connected by spacer rods passing through the mesh that are welded to each grid to ensure the dimensional stability of the pad. Monel mesh pads can also be furnished with special heavy duty supports grids where these are required to provide a working platform inside the vessel. Monel mesh pads can be installed either horizontally for vertical vapor flow or vertically for horizontal vapor flow. For vertical vapor flow, mesh pads are normally either 100mm or 150mm thick and for horizontal flow are normally greater at 150 to 200mm+ thick. Where mesh pad thickness exceeds 300mm, the unit is usually divided into 2 separate layers so that the sections will pass through normal vessel manways and in such cases wire screens are fitted between layers to maintain pad integrity during installation.

Mechanical Property Requirements

Characteristics:

Applications:

Chemical Composition, %

C | Mn | S | Si | Ni | Cu | Fe |

.30 max | 2.00 max | .024 max | .50 max | 63.0 min | 28.0-34.0 | 2.50 max |

Mechanical Property Requirements

Ultimate Tensile | Yield Strength (0.2% OS) | Elong. in 2 in. or 50mm (or 4D), min.,% | |

Cold Worked/SR | |||

Min | 87 KSi | 60 KSi | 20B |

Min | 600 MPa | 415 MPa | |

Characteristics:

1.Resistant to seawater and steam at high temperatures

2.Excellent resistance to rapidly flowing brackish water or seawater

3.Excellent resistance to stress corrosion cracking in most freshwaters

4.Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated

5.Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids

6.Excellent resistance to neutral and alkaline salt

7.Resistance to chloride induced stress corrosion cracking

8.Good mechanical properties from sub-zero temperatures up to 1020° F

9.High resistance to alkalis

Applications:

1.Marine engineering

2.Chemical and hydrocarbon processing equipment

3.Gasoline and freshwater tanks

4.Crude petroleum stills

5.De-aerating heaters

6.Boiler feed water heaters and other heat exchangers

7.Valves, pumps, shafts, fittings, and fasteners

8.Industrial heat exchangers

9.Chlorinated solvents

10.Crude oil distillation towers

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Monel Alloy

Monel Alloy Wire Mesh

Demister Pad

Mirror Demister

Monel Sheets

Metal Wire Mesh Demister

More>>