|

Heanjia Super-metals Co., Ltd.

|

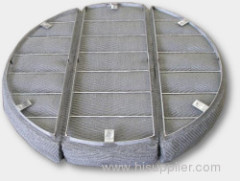

SAF2507 Stainless Steel Mist Eliminator SAF2507 Demister

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The high chromium and molybdenum content of SAF2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid.

SAF2507 Stainless Steel Mist Eliminator

The high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid. SAF2507 Mist Eliminator also provides excellent resistance to inorganic acids, especially those containing chlorides.

In dilute sulfuric acid contaminated with chloride ions, SAF2507 Mist Eliminator has better corrosion resistance than 904L Mist Eliminator, which is a highly alloyed austenitic steel grade specially designed to resist pure sulfuric acid.

The duplex structure of 2507 provides excellent resistance to chloride stress corrosion cracking (SCC). Because of its higher alloy content, 2507 is superior to 2205 in corrosion resistance and strength.

Technical Data:

Typical Limit Drop sizes = 3 microns

Mesh Pad Velocities = 450 fpm

Typical Mesh Pad pressure drop STP = 0.4w.c.

Mesh Pad + Profile Mist Eliminator Velocity = 1100 fpm

Typical Pressure drop for Mesh Pad + Profile Mist Eliminator combination= 0.6w.c.

Available specifications:

Diameter:1000-4100mm

Thinkness:100-200mm

Filtration rating: 98%-98.9%

Chemical Composition(%)

Alloy | C | Cr | Ni | Mo | N | Others |

SAF2507 | 0.020 | 25.0 | 7.0 | 4.0 | 0.27 | S=0.001 |

PREN = [Cr%] + 3.3 [Mo%] + 16 [N%] ≥ 40 | ||||||

Features:

Small liquid particles are inevitable during many manufacturing processes. These particles can cause lots of problems such as equipment corrosion, product contamination, and causing equipment damage. And it also can cause air pollution. Our demister pad is designed to remove nearly any type of particles.

Applications:

(1)Widely used in chemical, petroleum, tower manufacturing, pressure vessels and other industries in the gas-liquid separation device.

(2)For the air filter for gas separation.

(3)Mist Eliminator screen can be used as instruments of industrial instrumentation in the various buffers to prevent electrical interference shielding of electronic devices.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!