|

Heanjia Super-metals Co., Ltd.

|

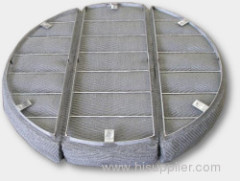

Inconel 625 Demister Pads

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Inconel 625 Demister Pads has a corrosion resistance to many environments. In mild environments such as atmosphere, fresh water and sea water.

Inconel 625 Demister Pads

Inconel 625 Demister Pads has a corrosion resistance to many environments. In mild environments such as atmosphere, fresh water and sea water, neutral salts and alkaline media there is almost no attack. In more aggressive media nickel and chromium resist oxidizing attack, while nickel and molybdenum resist reducing environments. Molybdenum provides exceptional resistance to pitting and crevice corrosion, and niobium stabilizes against sensitization and intergranular corrosion.

The nickel content makes Inconel 625 ressentially free from chloride ion stress corrosion cracking.

Inconel 625 Demister Pads also has excellent corrosion fatigue properties.

Technical Data:

Typical Limit Drop sizes = 3 microns

Mesh Pad Velocities = 450 fpm

Typical Mesh Pad pressure drop STP = 0.4w.c.

Mesh Pad + Profile Mist Eliminator Velocity = 1100 fpm

Typical Pressure drop for Mesh Pad + Profile Mist Eliminator combination= 0.6w.c.

Available specifications:

Diameter:1000-4100mm

Thinkness:100-200mm

Filtration rating: 98%-98.9%

Chemical Composition(%):

Alloy | % | Ni | Cr | Mo | Al | Nb | C | Co | Mn | Ti | Si | Fe |

Inconel 625 | Min. | 20.0 | 8.0 | 0.80 | 3.15 | |||||||

Max. | 58.0 | 23.0 | 10.0 | 1.50 | 4.15 | 0.1 | 1.0 | 0.50 | 0.40 | 0. 5 | 5.00 |

Mechanical Properties:

Item | Annealed | Solution annealed |

Tensile Strength, (Mpa) | 830 | 690 |

Yield Strength (0.2% Offset), (Mpa) | 415 | 275 |

Elongation, % | 30 | 30 |

Applications:

Inconel 625 Demister Pads is widely used in evaporators, refining vaccum towers, refining lube towers, steam drums, absorbers, scrubbers, separators vessels and knock out drums and any process vessels handling liquid and vapor where complete separation of entrained liquid droplets is desired from gas/vapor phase.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Demister Pad

Mirror Demister

Inconel Alloy Wire

Metal Wire Mesh Demister

Brake Pads

Mouse Pads

More>>