|

Heanjia Super-metals Co., Ltd.

|

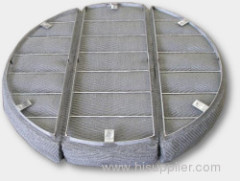

Inconel 600 Mesh Demister Inconel 600 Mesh Pad

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Inconel 600 Demister are well suited to remove mechanically formed entrainment from packed and trayed process towers, spray columns, venture scrubbers

Inconel 600 Mesh Demister

Inconel 600 Characteristics:

1. Resistant to a wide range of corrosive media. The chromium content gives better resistance than Alloy 200 and 201 under oxidizing conditions, at the same time the high nickel gives good resistance to reducing conditions.

2. Virtually immune to chlorine ion stress corrosion cracking.

3. Demonstrates adequate resistance to organic acids such as acetic, formic and stearic.

4. Excellent resistance to high purity water used in primary and secondary circuits of pressurized nuclear reactors.

5. Little or no attack occurs at room and elevated temperatures in dry gases, such as chlorine or hydrogen chloride. At temperatures up to 550C in these media, this alloy has been shown to be one of the most resistant of the common alloys.

6. The alloy also resists ammonia bearing atmospheres, as well as nitrogen and carburizing gases.

Inconel 600 Demister are well suited to remove mechanically formed entrainment from packed and trayed process towers, spray columns, venture scrubbers and other gas scrubbing devices. They are also a widely used de-entrainment device in knock out drums and separators.

Technical Data:

Typical Limit Drop sizes = 3 microns

Mesh Pad Velocities = 450 fpm

Typical Mesh Pad pressure drop STP = 0.4w.c.

Mesh Pad + Profile Mist Eliminator Velocity = 1100 fpm

Typical Pressure drop for Mesh Pad + Profile Mist Eliminator combination= 0.6w.c.

Available specifications:

Diameter:1000-4100mm

Thinkness:100-200mm

Filtration rating: 98%-98.9%

Alloy | Ni | Cr | Fe | C | Mn | S | Si | |

Inconel 600 | Max | 17.0 | 10.0 | 0.15 | 1.0 | 0.015 | 0.5 | |

Min | 72.0 | 14.0 | 6.0 |

Mechanical Properties:

Item | Annealed | Cold Worked |

Tensile Strength, KSI (Mpa) | 90(620) | 110(760) |

Yield Strength (0.2% Offset), KSI (Mpa) | 40(275) | 85(585) |

Elongation, % | 25 | 10 |

Applications:

Inconel 600 Mesh Demister is widely used in evaporators, refining vaccum towers, refining lube towers, steam drums, absorbers, scrubbers, separators vessels and knock out drums and any process vessels handling liquid and vapor where complete separation of entrained liquid droplets is desired from gas/vapor phase.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!