|

Heanjia Super-metals Co., Ltd.

|

Nickel Chromium Mesh

| Payment Terms: | T/T,L/C,D/A,D/P, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Nickel Chromium Mesh/Screen: Ni80Cr20:Good anti-corrosion, resisting to oxidation at high temperatures. High melting point of about 1400 °C (2552 °F)

Nickel Chromium Mesh Wire Mesh/Screen

Nickel Chromium Wire Mesh/Screen is corrosion resistant and has a high melting point of about 1400 °C (2552 °F). Nickel Chromium Wire Mesh has very good resistance to oxidation at high temperatures. The ultimate tensile strength of Nickel Chromium Wire Mesh is 105,000 PSI (Pounds per Square Inch), yield strength is around 50,000 PSI and modulus of elasticity is 31 x 106 PSI.

Nickel Chromium Wire Mesh/Screen is widely used to process heat tratment for electronic parts and components. Nickel Chromium Wire Meshs have many advantages, such as deformation ability, thermal stability, mechanical character, shockproof ability in thermal state and anti-oxidization. For heating, resistance Conveyor Belt must be stable in air when hot.

Nickel Chromium Wire Mesh/Screen forms a protective layer of chromium oxide. Due to Nickel Chromium Wire Mesh's relatively high resistivity and resistance to oxidation at high temperatures, Nickel Chromium Wire Mesh is widely used in heating elements, electric furnace heating and heat-treating processes in the chemical, mechanical, metallurgical and defense industries, such as electric ovens, toasters, vacuum coating, inner components of vacuum valves. Typically, Nickel Chromium Wire Mesh is widely used to process heat treatment in electronic industry.

Nickel Chromium Wire Mesh/Screen is an ideal material, because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time. Material beneath the Conveyor Belt will not oxidize, preventing the Conveyor Belt from breaking or burning out. So Nickel Chromium Wire Mesh is good for anti-corrosion and high resistant co-efficiency. So Nickel Chromium Wire Mesh is applicable for heat treatment, air-carbon furnace, chemical industry, machinery, metallurgy.

Nickel Chromium Wire Mesh's metallurgical structure confers them a very good plasticity when cold. Resistance to oxidation (they are not sensitive to aggressions of humid air). Low embrittlement at high temperature, good plasticity – easier to give them a shape compared with FeCrAl (lower mechanical characteristics allow indeed a good control of elasticity of the product during shaping (coiling, folding, drawing). Good resistance to creeping (more important than ferritic alloys) which is important during conception of a resistance presenting big heights of waves. Maximal temperature recommended in the furnace: 1922 / 2012 °F in order to obtain a reasonable life time of the elements.

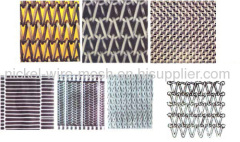

Mesh Weaving Method

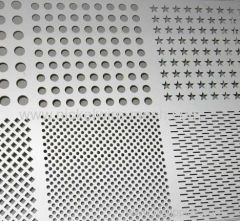

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Nickel chromium alloys Comparison: | ||||||

Material | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

Component % | Ni | Remanent | Remanent | 55.061.0 | 34.037.0 | 30.034.0 |

Cr | 20.023.0 | 28.031.0 | 15.018.0 | 18.021.0 | 18.021.0 | |

Fe | ≤1.0 | ≤1.0 | Remanent | Remanent | Remanent | |

Highest temperature | 1200 | 1250 | 1150 | 1100 | 1100 | |

Melting point | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistance ratio μΩ·m,20 | 1.09±0.05 | 1.18±0.05 | 1.11±0.05 | 1.04±0.05 | 1.04±0.05 | |

Extend ratio % | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

Specific heat J/g. | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

coefficient of heat conductivity KJ/m.h | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Wire expand coefficient a×10-6/201000 | 18 | 17 | 17 | 19 | 19 | |

Micro-organization | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetism | Non-magnetism | Non-magnetism | Non-magnetism | Non-magnetism | Non-magnetism | |

Product Description: The product produced by us is of good quality and is priced reasonably.

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Nickel Chromium Wire Mesh

Nickel Chromium

Nickel Chromium Alloy

Nickel Chromium Wire

Nickel Mesh

Chromium

More>>