|

Heanjia Super-metals Co., Ltd.

|

Nickel Chromium alloy Cr15Ni60 Wire Mesh

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Nichrome 60/15 wire mesh/screen: Used as carrier belt or conveyor in high temperature. heating devices operating up to 1000 ℃(1850F).

Nichrome 60/15 Wire Mesh/Screen

Nichrome60 (Cr15Ni60) wire mesh/screen is commonly used as carrier belt or conveyor in high temperature. It is an accepted material for heating devices operating up to 1000 ℃(1850F). This encompasses most pluggable power cord domestic heating appliances and those heating units of medium temperatures which do not require the unsurpassed quality of Ni80-Cr20 alloy.

To ensure the quality of our product, we can produce the product with raw materials from the international suppliers. Every batch of product can be tracked to the original raw material supplier. We co-operate with international suppliers like Allvac(ATI), Bohler, Carpenter, Dunkirk, Gloria, OttoKumpu, SMC, ThyssenKrupp VDM, Valbruna, etc.

Nominal Composition of Nichrome 60/15 wire mesh/screen:

Nickel% | Iron% | Carbon | Manganese | |

60 | 15 | Balance | 0.08 max | 1 max |

Typical Properties of Nichrome 60/15 wire mesh/screen:

Temp. Coeff. Of Resistance Km x 10-6/°C | Specific Resistance microhm-cm (20°C) | Linear Expansion Coeff. X 10-6 /°C |

170 (20-500 °C) | 112 | 17 (20-1000°C) |

Density (weight per cubic inch): 0.2979 lbs. Specific gravity (68°F /20°C): 8.247 Magnetic Attraction: Para Thermal conductivity watts/cm/°C (100°C/212°F): 0.132 Approximate melting point: 2462°F (1350°C) Maximum operating temp: 1652°F (900°C) |

Typical Tensile Strength and elongation

Annealed | |

UTS | 600-900 N/mm2 |

Elongation | >20 |

Applications of Nichrome 60/15 wire mesh/screen:

1. Heating Elements

Manufacturers mainly use nichrome wire to make coils for heating elements.

2. Hot-Wire Cutter

It cuts through materials like polystyrene foam, somewhat like a wire cheese cutter. The heat does the cutting, and makes a smoother and more even cut than a saw or knife could achieve.

3. High-Temperatures Uses

Because of nichrome wire's strength at extremely high temperatures and its flexibility, pottery enthusiasts use it to assemble backyard kilns and to hold the shape of pottery items while they bake.

4. Igniters

Nichrome Wire heats up rapidly with even a small amount of electricity; it makes safe igniters (sometimes called electric matches) to light the fuses of fireworks and model rockets.

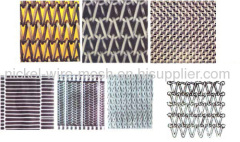

Mesh Weaving Method

Mesh Weaving Method

Expanded Mesh |

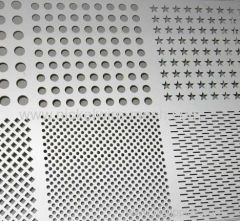

Perforated Mesh |

Twill Weave mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Dutch Weave Mesh |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Plain Weaving Mesh |

Wire Diameter: 0.05mm-10.0mm, 0.002 Inch to 0.3937 Inch

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Product Description: The product produced by us is of good quality and is priced reasonably.

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Nickel Chromium Wire Mesh

Nickel Chromium Alloy

Nickel Chromium Wire

Nickel Chromium

Nickel Alloy Wire

Nickel Copper Alloy Wire

More>>