|

Heanjia Super-metals Co., Ltd.

|

Mesh Belt Conveyor

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Mesh Belt Conveyor : Used for food processing, heat treatment, forging, foundry, etc.Used in application like closed wire mesh belts for flexibility.

MESH BELT CONVEYOR

Our Company is into the manufacturing of METAL / WIRE MESH CONVEYOR BELTSwhich are used in various industries such as food processing, heat treatment, forging, foundry, glass, ceramics, automotive, furnace etc.

Our metal conveyor belts are suitable for any application like, including closed wire mesh belts for flexibility and conveying small parts, belts which having large opening for easy flow of water or air and for cleaning of your products,and smooth surface belts for easy and accurate transfer.

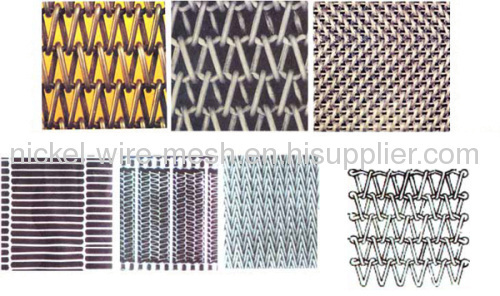

We make various types of Conveyor belts and given below are the types and there advantages:-

1. Ladder Belt

Our Company is into the manufacturing of METAL / WIRE MESH CONVEYOR BELTSwhich are used in various industries such as food processing, heat treatment, forging, foundry, glass, ceramics, automotive, furnace etc.

Our metal conveyor belts are suitable for any application like, including closed wire mesh belts for flexibility and conveying small parts, belts which having large opening for easy flow of water or air and for cleaning of your products,and smooth surface belts for easy and accurate transfer.

Our metal conveyor belts are used to convey metal parts through copper and aluminium brazing furnace, iron parts through sintering furnace, chemical products through oven, dryers and all process which involve washing, annealing and polishing. In the food processing industries our belts are used to bake, cook, freeze, salt etc.

We make various types of Conveyor belts and given below are the types and there advantages:-

1. Ladder Belt

Usually these belts are called Chocolate Conveyor belts which are made by assembling the successively bent wires.

Advantages of Ladder Belt:-

1.The sprocket drive ensures positive and stable running.

2.The rotation diameter is small, so that smooth products transfer is ensured.

3.Easy washing is ensured.

4.Because of large open area, high air permeability and dehydration capacity are ensured.

Applications of Ladder Belt:-

It has a wide range of applications in processing meat, poultry, seafood, cereals, candy and electronic P.C boards.

Standard Specification of Ladder Belt:-

Pitch (mm) | 5 - 6 - 7 - 7 - 10 - 13 - 15 - 15 - 18 - 20 - 20 - 20 - 19 |

Wire Diameter (mm) | 1 - 1 - 1 - 1 - 1 - 2 - 2 - 2 - 3 - 3 - 3.2 - 3.5 - 5 |

Minimum Span (mm) | 30 - 30 - 30 - 30 - 30 - 30 - 40 - 50 - 60 - 100 - 130 - 150 - 300 |

Overall Width (mm) | 300-4200 |

2. Balanced Belt

The left-wound and right-wound spirals are alternately arranged and jointed with the pre-crimped roads.

Winding Rod Balance Series (BW)

Winding rod balance belts are produced with alternating right and left hand spirals joined by crimped connector rods. Because of its big openings and sparse, belts of this series are designed as winding rod to avoid the deviation caused by the transverse shaking of spirals. It is used for conveying objects of large volumes and light weight.

Applications of Balalnced Belts:-

It is the most widely used in many food processes from draining to cooling as well as in industrial sectors. Such as annealing glass, automation lines under high-temperature, in heat treating and drying.

3. Chain Driven Belt

These belts are made by fitting chains to both sides of ordinary wire conveyor belt.

Belt and chain are synchronized through stays (cross supports).

Advantages of Chain driven Belt:-

1.Because chain is driven by sprocket, maendering does not occur.

2.Various types of chain can be applied by adjusting belt pitch.

3.It is easy to attach side guard and product stopper in combination with chain and stay.

Applicable Belts:

It is possible to fit almost all types of belts, including woven wire.

Selection of wire conveyor belt with chain

Selection of wire conveyor belt with chain

1.Belt selection

Select belt type, wire diameter and pitch according to type, shape, size and weight of products.

2.Selection of Chain and Support

Select chain and stay according to the product conditions, belt width, length, speed, machine layout etc

4. High Temperature Belt

These belts can be used for sintering, brazing, hardening, firing, tempering lehr etc.

It is important to select belt type and material which can endure high temperature.

It is important to select belt type and material which can endure high temperature.

Components of typical material

Nickel chromium alloys Comparison: | ||||||

Material | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

Component % | Ni | Remanent | Remanent | 55.061.0 | 34.037.0 | 30.034.0 |

Cr | 20.023.0 | 28.031.0 | 15.018.0 | 18.021.0 | 18.021.0 | |

Fe | 1.0 | 1.0 | Remanent | Remanent | Remanent | |

Highest temperature | 1200 | 1250 | 1150 | 1100 | 1100 | |

Melting point | 1400 | 1380 | 1390 | 1390 | 1390 | |

Density g/cm3 | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

Resistance ratio | 1.09/0.05 | 1.18/0.05 | 1.11/0.05 | 1.04/0.05 | 1.04/0.05 | |

Extend ratio % | 20 | 20 | 20 | 20 | 20 | |

Specific heat J/g. | 0.44 | 0.461 | 0.494 | 0.5 | 0.5 | |

coefficient of heat conductivity KJ/m.h | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

Wire expand coefficient 10-6/201000 | 18 | 17 | 17 | 19 | 19 | |

Micro-organization | Austenite | Austenite | Austenite | Austenite | Austenite | |

Magnetism | Non-magnetism | Non-magnetism | Non-magnetism | Non-magnetism | Non-magnetism | |

5. Wire Ring Belt

Usually this belt is called Eye Link Belt. Wires are formed into eye-links and jointed with rods.

Mesh opening is increased by inserting collars or by spot welding

Mesh opening is increased by inserting collars or by spot welding

Advantages of Wire Ring Belt:

1.Positive sprocket drive ensures stable running.

2.Belt has smooth surface and unstable products can be carried.

3.Washing is easy.

4.Aperture can be increased for high air permeability and hydration capacity.

5.Reinforcement plate links are made for heavy load and high speed.

6. Compound Balanced Belt

The left-wound and right-wound spirals are fitted tightly together alternately and joined with

Straight rods. A4 uses 4 rods for one spiral to joint. A3 uses 3 rods for one spiral to joint.

Advantages of Compoud Balanced Belt:

1.Since the surface is flat and smooth, the belts can carry small items and unstable products.

2.The allowable tension is high, so that heavy load can be transported.

3.The belt strength against pressure is high, so the belt can be used for processing under pressure.

4. The belt can be used at high temperature.

5. The belt can be used for textile products refining and cleaning process.

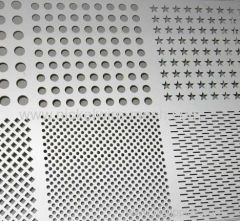

7. Flat Wire Belt

The flat wires are arranged in the form of lattice and jointed with the straight rods

Advantages of Flat Wire Belt:

1. The positive sprocket drive ensures stable running.

2.Large open area ensures high air permeability and dehydration capacity.

3. The belt can be easily washed.

4. Because the belt has smooth surface, it can carry unstable products.

8. Conveyor Belts for Highest Conveying Capacities

Wear-resistant, rot and corrosion-resistant, resistant to chemicals and thermally stable, our steel cord conveyor belts provide long years of service while requiring little maintenance.

Properties of COnveyor Belts for highest Conveying capacities :

1. Steel cord as tension member (ST 500 - ST 10 000)

2. up to 6,400 mm wide

3. Few splices & transition areas

4. High breaking load at maximum conveying capacity

5. Wear resistant, rot- and corrosion-resistant, resistant to chemicals and thermally stable

6. Fire retardant and anti-static

7.Roll weights of up to 60 tonnes

8. For extreme loads, the conveyor belts are equipped with an additional steel-cord or traverse reinforcement

9.Little maintenance required

Applications:

Also for applications underground

For long distances & large conveying heights

9. Conveyor belts and processing belts Siegling Transilon

Certain conveying and processing tasks require mechanical, physical or chemical belt properties which are made possible only by special production processes, combination of materials or finishing.

1.Profiles and Sidewalls

2.Top Face Patterns

3.Modifying Belts

4.Belt Edge Sealing

5. Knife Edge Belts

6. Curved Belts

7. Antistatic Belts

8. NA (Non-antistatic)

9. HC (Highly-conductive)

10. Accumulation Belts

The combination of materials -

The standard Siegling Transilon construction consists of polyester fabric as tension member with synthetic or elastomer coatings. Siegling Transilon is used successfully in industrial, commercial and service companies worldwide. The standard product range includes over 120 various conveyor belt types and constructions for the most diverse of application requirements.

We offer special product ranges for numerous industries and applications.

Depending on the belt type Siegling Transilon offers the following properties and benefits:

The properties | The advantages |

virtually stretchless | small take-up ranges are possible |

dimensionally stable | unaffected by fluctuations in humidity and temperature |

low-noise | environmentally friendly by reducing noise emissions |

longitudinally flexible | drums and knife edges of small diameter may be used |

laterall stiff | wide belts run flat |

light and thin | even long belts can be handled easily |

rugged | tough and wear-resistant, wide range of applications |

troughable | adapts easily to troughed rollers |

flame-retardant | complies with EN 20340 and DIN 22103 |

highly conductive | measured in accordance with DIN 22104 and ISO 284 |

Product Description: The product produced by us is of good quality and is priced reasonably.

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Mesh Conveyor Belt

Plastic Belt Conveyor

Horizontal Belt Conveyor

Nylon Belt Conveyor

Used Belt Conveyor

Modular Plastic Belt Conveyor

More>>