|

Heanjia Super-metals Co., Ltd.

|

Wire Mesh Carrier

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We have developed technique to produce wire mesh carriers used in extreme environments, such as strong acid or alkali or corrosive environments.

WIRE MESH CARRIER

We have developed technique to produce wire mesh carriers used in extreme environments, such as strong acid or alkali or corrosive environments or high temperature environments. The wire mesh products we produce are all suitable for applications in extreme environments technically. Wire mesh carrier can be produced in various shapes, sizes and materials.

1.Wire Mesh Carrier/Basket for high temperature:

The kind of Wire mesh carrier/basket is made of materials with great resistance to high temperature environments. The materials include Nickel chrome alloys, FeCrAl alloys, Tungsten or molybdenum, etc. The most typical one is nickel chrome (nichrome) alloy wire mesh carrier; it has the most outstanding properties.

Nichrome wire mesh carrier/ basket have a high melting point of about 1400ºF (2552ºC ) while resisting to corrosion. Nichrome has very good resistance to oxidation at high temperatures (Maximal temperature recommended: 1922 / 2012 ºCin order to obtain a reasonable life time of the elements). Typically, it is widely used as carrier in passive component industry during heat treatment process.

Nichrome wire mesh carrier has many advantages, such as thermal stability, mechanical character, shockproof ability in thermal state and anti-oxidization. For heating, the carrier must be stable in air when hot. It is widely used in heat-treating processes in the chemical, mechanical, metallurgical and defense industries, such as toasters, vacuum coating.

2. Wire Mesh Carrier for acid or alkali or corrosive environments:

The kind of Wire mesh carrier/basket is made of materials with great resistance to strong acid or alkali or other corrosive working environments. The materials include nickel, monel, Incoloy, Inconel, Hastelloy, titanium, silver, etc. They are all widely used as carrier in extreme environments.

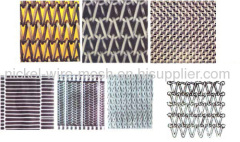

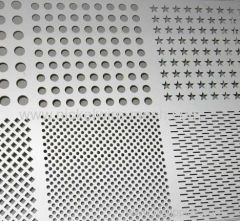

The carriers can be made with mesh woven with wire, perforated metal or expanded metal. The wire mesh carrier is produced for commercial uses or for industrial uses which may need to withstand a lot of weight and wear and tear in hard environments.

Typically, customers submit us the detailed application requirements, such as ultrasonic cleaning, parts degreasing, parts washing, curing, or heat treating, etc. This ensures that the end products are the right material, size, shape and finish and perfect for your application.

high temperature Resisting | Nickel chromium alloys: Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni35, Cr20Ni30 |

FeCrAl alloys: 1Cr13Al4, 0Cr25Al5, 0Cr21Al6, 0Cr23Al5, 0Cr21Al4, 0Cr21Al6Nb | |

Tungsten, Molybdenum | |

Corrosion Resisting | Nickel200/201, |

Monel 400, Monel K500, | |

Inconel 600, Inconel 625, Inconel 718, Inconel X750 , | |

Incoloy 800H, Incoloy 825, alloys, | |

Hastelloy alloys, Titanium, Silver | |

Special Materials | 904L, 826, SS304, SS306, etc. |

Gh2132, GH3030, GH901, | |

F44, F51, F52, F53, F55, | |

17-4PH(630), 15-5PH | |

13-8MoPH, 17-7PH, XM-19, 347, 347H |

Product Description: The product produced by us is of good quality and is priced reasonably.

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!