|

Heanjia Super-metals Co., Ltd.

|

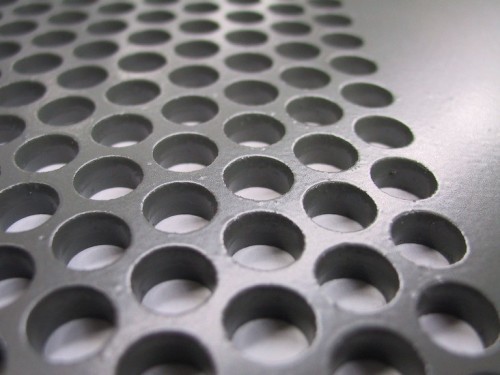

Stainless Steel grade 904L Perforated Metal

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The Stainless Steel Grade 904L Perforated Metal provides broad resistance to the powerful acids, chloride shocks, pitting and crevice corrosion.

The Stainless Steel Grade 904L Perforated Metal consists of copper providing broad resistance to the powerful acids, chloride shocks, pitting and crevice corrosion. It shows non magnetic nature in the all conditions, highly weldable and preserves its hardness lower than the cryogenic temperatures.

Perforated metal is basically a sheet metal consists of perforated, embossed or slotted plates. It is basically made by puncturing the material by using a tool. The perforated metal is made of specific metal that has holes made by a die. On the base of kind of metal, the ratio of hole size to material is adjusted. We have professional and expert die and tool makers who perform the task quickly.

Chemical composition of Stainless Steel Grade 904L Perforated Metal:-

Physical properties of Stainless Steel Grade 904L Perforated Metal:-

Mechanical properties of Stainless Steel Grade 904L Perforated Metal:-

Characteristics of Stainless Steel Grade 904L Perforated Metal:-

Applications of Stainless Steel Grade 904L Perforated Metal:-

Perforated metal is basically a sheet metal consists of perforated, embossed or slotted plates. It is basically made by puncturing the material by using a tool. The perforated metal is made of specific metal that has holes made by a die. On the base of kind of metal, the ratio of hole size to material is adjusted. We have professional and expert die and tool makers who perform the task quickly.

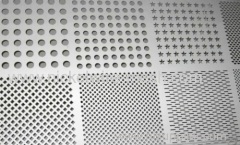

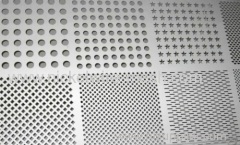

We offer the perforated metal in the following shapes: Circle, square, triangle, hex, oval and various other shapes. We utilize the latest tools to puncture the holes in the different shapes making the process more economical and spectacular.

Chemical composition of Stainless Steel Grade 904L Perforated Metal:-

C | Mn | Si | P | S | Cr | Mo | Ni | N | |

Min Max | - 0.020 | - 2.00 | - 1.00 | - 0.045 | - 0.035 | 19.0 23.0 | 4.0 5.0 | 23.0 28.0 | 1.0 2.0 |

Physical properties of Stainless Steel Grade 904L Perforated Metal:-

Density(kg/m3) | Elastic Modulus (GPa) | Mean coeff. Of expansion(0-100°C) (μm/m/°C) | Thermal conductivity (W/m.K) at20°C | Specific heat (0-100°C) (J/Kg.k) | Electric resistivity (nΩ.m) |

8000 | 200 | 15 | 13 | 500 | 850 |

Mechanical properties of Stainless Steel Grade 904L Perforated Metal:-

Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa)min | Elongation (% in 50mm) min | Hardness |

490 | 220 | 35 | 70-90 |

Characteristics of Stainless Steel Grade 904L Perforated Metal:-

1.Resistance to oxidation in all corrosive media and pitting and crevice corrosion

2.Tremendous toughness

3.Good Weldability

Applications of Stainless Steel Grade 904L Perforated Metal:-

1.Seawater cooling device.

2.Oil filtration.

3.Pulp and paper treatment.

4.Acid processing plants.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Steel Perforated Metal

Stainless Perforated Metal

Perforated Stainless Steel Mesh

Perforated Stainless Steel Sheet

Stainless Steel Perforated Sheet

Stainless Steel Perforated Plate

More>>