|

Heanjia Super-metals Co., Ltd.

|

321 Stainless Steel Wire Mesh Screen Netting

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

321 Stainless Steel Wire Mesh/Screen: used in particular applications within the sensitizing temperature range

321 stainless steel wire mesh/screen is a titanium-stabilised version of Grade 304 wire mesh/screen, used in particular applications within the sensitizing temperature range. 321 stainless steel wire mesh's resistance to sensitization, coupled with its higher strength at high temperature makes it suitable in application where Grade 304 will become sensitized, or where Grade 304L has insufficient hot strength. It is not subject to weld decay (intergranular corrosion) when exposed to mildly corrosive environments. However, welded Grade 321 must never be used in highly oxidizing environments as it is liable to 'Knife-line' attack.

321 Stainless Steel Typical Applications

321 stainless steel is used almost exclusively for service within the sensitizing temperature range (450-850oC). In welded ambient temperature applications it has been replaced by Grade 304L. Some typical areas of application are: Furnace components, super-heater and afterburner parts, compensators and expansion bellows.

321 Stainless Steel wire mesh/screen Chemical Composition (ASTM A240)

C | Mn | P | S | Si | Cr | Ni | Ti | |

Analysis | 0.08 max | 2.0 max | 0.045 max | 0.030 max | 1.0 max | 17.0 - 19.0 | 9.0 - 12.0 | 5X%C min 0.5 max |

Typical | 0.06 | 1.2 | 0.020 | 0.020 | 0.5 | 17.5 | 9.4 | 0.48 |

321 Stainless Steel wire mesh/screen Mechanical Properties at Room Temperature

Typical | Minimum | |

Tensile Strength, MPa | 580 | 515 |

Proof Stress (0.2 % offset), MPa | 280 | 205 |

Elongation (Percent in Lo = 5.65 So) | 60 | 40 |

Hardness (Brinell) | 163 | - |

Endurance (fatigue) limit, MPa | 260 | - |

321 Stainless Steel wire mesh/screen Properties at Elevated Temperatures (Short Time Elevated Temperature Tensile Strength)

Temperature, oC | 600 | 650 | 700 | 750 | 800 | 850 |

Tensile Strength, MPa | 390 | 329 | 280 | 230 | 190 | 140 |

Creep data (Stress to develop a creep rate of 1% in the indicated time at the indicated temperature)

Time | Temperature oC | 550 | 600 | 650 | 700 | 800 |

10 000 h | Stress MPa | 180 | 100 | 70 | 40 | 10 |

100 000 h | Stress MPa | 120 | 80 | 50 | 25 | 5 |

Creep Rupture Stress

Time | Temperature oC | 500 | 600 | 650 | 700 | 800 |

1 000 h | Stress MPa | 270 | 180 | 140 | 70 | 30 |

10 000 h | Stress MPa | 240 | 130 | 90 | 50 | 10 |

100 000 h | Stress MPa | 200 | 90 | 50 | 15 | 5 |

Recommended Maximum Service Temperature (Oxidising Conditions)

Continuous Service 950oC | Intermittent Service 870oC |

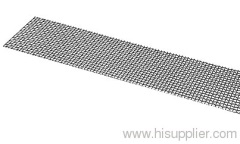

Wire Mesh Specifications:

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

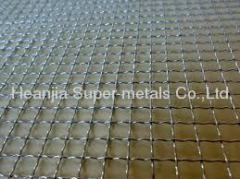

Available Wire Mesh weaving forms:

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Available Wire Mesh weaving forms:

Expanded Mesh |

Perforated Mesh |

Twill Weave mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Dutch Weave Mesh |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Plain Weaving Mesh |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Steel 321

Stainless Steel Wire Netting

Stainless Steel Mesh Screen

Stainless Steel Wire Screen

Stainless Steel Wire Mesh

Stainless Steel Mesh Wire

More>>