|

Heanjia Super-metals Co., Ltd.

|

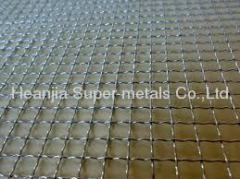

2304 Stainless Steel Wire Mesh

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Alloy 2304 has corrosion resistance properties similar to 316L,its yield strength, are twice those of 304/316 austenitic grades.

Mesh: 0.5-250 mesh.

Super Duplex 2304 Stainless Steel

Alloy 2304(UNS S32304) is a 23% chromium, 4% nickel, molybdenum-free duplex stainless steel. The Alloy 2304 has corrosion resistance properties similar to 316L. Furthermore, its mechanical properties, i.e., yield strength, are twice those of 304/316 austenitic grades. This allows the designer to save weight, particularly for properly designed pressure vessel applications.

The alloy is particularly suitable for applications covering the -50°C/+300°C (-58°F/572°F) temperature range. Lower temperatures may also be considered but need some restrictions, particularly for welded structures.

With its duplex microstructure and low nickel and high chromium contents, the alloy has improved stress corrosion resistance properties compared to 304 and 316 austenitic grades.

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Corrosion Resistance

Because of its high chromium content (23%) the corrosion resistance properties of 2304 are almost equivalent to those of 316L.

The 23% chromium and 0.1% nitrogen additions explain why 2304 duplex stainless steel behaves much better than Alloy 316L when considering pitting and crevice corrosion resistance.

Its corrosion rate in boiling nitric acid (65%) is higher than that of Alloy 316L. Due to its high yield strength, the alloy performs well in abrasion/corrosion applications.

Chemical Analysis

C | Cr | Ni | Mo | N | Others |

0.020 | 23 | 4 | 0.2 | 0.1 | S=0.001 |

PREN (Cr%) + 3.3 (Mo%) = 16 (N%) ≥ 24 | |||||

Mechanical Properties-- Tensile Properties (Minimum Values)

°C | Rp 0.2 MPa | Rp 1.0 MPa | Rm MPa |

20 | 400 | 440 | 600 |

100 | 330 | 365 | 570 |

200 | 280 | 310 | 530 |

300 | 230 | 260 | 490 |

°F | YS 0.2% KSI | YS 1.0% KSI | UTS KSI | Elongation % |

68 | 58 | 64 | 87 | 25 |

212 | 48 | 53 | 83 | 25 |

392 | 41 | 45 | 77 | 20 |

572 | 33 | 38 | 71 | 20 |

Alloy 2304 must not be used for a long time at temperatures higher than 300°C (572°F), where precipitation hardening phenomenon occurs.

Hardness

Average (5) | HV10 180-230 | HB 180-230 | HRC _ 20 |

Applications

1)Generally where 304 and 316L are used

2)Pulp and paper industry (chip storage tanks, white and black liquor tanks, digestors)

3)Caustic solutions, organic acids (SCC resistance)

4)Food industry

5)Pressure vessels (weight savings)

6)Mining (abrasion/corrosion)

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Steel Wire Mesh

Stainless Steel Mesh Wire

Stainless Steel Welded Wire Mesh

Stainless Steel Crimped Wire Mesh

Stainless Steel Woven Wire Mesh

Stainless Wire Mesh

More>>