|

Heanjia Super-metals Co., Ltd.

|

Haynes 214 Perforated Metal

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The Haynes 214 Perforated Metal causes considerably high resistance to oxidation at the wide range of temperatures and can be utilized up to 955°C.

The Haynes 214 Perforated Metal causes considerably high resistance to oxidation at the wide range of temperatures and can be utilized up to 955°C or 1750°F and creates a secure layer of chromium and aluminum oxides to avoid further oxidation. It introduces supreme resistance to carburization, nitriding, and chlorides.

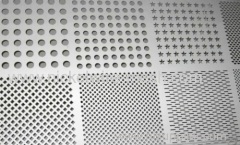

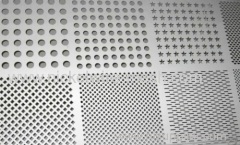

Perforated metal is basically a sheet metal consists of perforated, embossed or slotted plates. It is basically made by puncturing the material by using a tool. The perforated metal is made of specific metal that has holes made by a die. On the base of kind of metal, the ratio of hole size to material is adjusted. We have professional and expert die and tool makers who perform the task quickly.

Chemical Composition of Hayness 214 Perforated Metal

Physical Properties of Hayness 214 Perforated Metal

Characteristics of Hayness 214 Perforated Metal

Applications of Hayness 214 Perforated Metal

Perforated metal is basically a sheet metal consists of perforated, embossed or slotted plates. It is basically made by puncturing the material by using a tool. The perforated metal is made of specific metal that has holes made by a die. On the base of kind of metal, the ratio of hole size to material is adjusted. We have professional and expert die and tool makers who perform the task quickly.

We offer the perforated metal in the following shapes: Circle, square, triangle, hex, oval and various other shapes. We utilize the latest tools to puncture the holes in the different shapes making the process more economical and spectacular.

Chemical Composition of Hayness 214 Perforated Metal

Ni | Cr | Al | Fe | Mn | Si | Zr | B | Y | C |

75 % | 16% | 4.5% | 3% | 0.5% | 0.2% | 0.1% | 0.01% | 0.01% | 0.05% |

Physical Properties of Hayness 214 Perforated Metal

Density | 8.05 g/cm.3 |

Melting Temperature | 1355-1400°C |

electrical Resistivity | 135.9 microhm-cm |

Thermal Conductivity | 12.0 W/m-K |

Specific Heat | 452 J/Kg-K |

Mean Coefficient of Thermal expansion | 13.3X10-6m/m-°C |

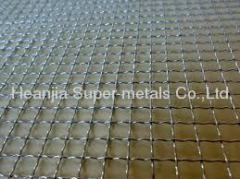

Characteristics of Hayness 214 Perforated Metal

1.Optimum Ductility at room temperature

2.Exceptionally high resistance to corrosion at high temperatures

3.Resistance to oxidation

4.Resistance to carburization, nitriding, and chlorides.

Applications of Hayness 214 Perforated Metal

1.Gas Turbines

2.Furnace Flame Hoods

3.Incinerator Internals

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Perforated Metal

Perforated Metal Sheet

Perforated Metal Mesh

Galvanized Perforated Metal

Galvanized Perforated Metal Mesh

Brass Perforated Metal

More>>