|

Heanjia Super-metals Co., Ltd.

|

316 Stainless Steel Wire Mesh Screen Netting

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

316L Stainless Steel Wire Mesh/Screen: immune from sensitisation, higher creep, stress to rupture and tensile strength at elevated temperatures

316L Stainless Steel Wire Mesh/Screen, the low carbon version of 316 wire mesh/screen and is immune from sensitisation (grain boundary carbide precipitation). Thus it is extensively used in heavy gauge welded components (over about 6mm). The molybdenum gives 316SS wire mesh/screen better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. Compared to chromium-nickel austenitic stainless steels, 316L stainless steel offers higher creep, stress to rupture and tensile strength at elevated temperatures. The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures.

316L Stainless Steel Wire Mesh/Screen Key Properties

1: Corrosion Resistance

Excellent in a range of atmospheric environments and many corrosive media - generally more resistant than 304. Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 60°C. Considered resistant to potable water with up to about 1000mg/L chlorides at ambient temperatures, reducing to about 500mg/L at 60°C.

316 is usually regarded as the standard "marine grade stainless steel", but it is not resistant to warm sea water. In many marine environments 316 does exhibit surface corrosion, usually visible as brown staining. This is particularly associated with crevices and rough surface finish.

2: Heat Resistance

Good oxidation resistance in intermittent service to 870°C and in continuous service to 925°C. Continuous use of 316 in the 425-860°C range is not recommended if subsequent aqueous corrosion resistance is important. Grade 316L is more resistant to carbide precipitation and can be used in the above temperature range. Grade 316H has higher strength at elevated temperatures and is sometimes used for structural and pressure-containing applications at temperatures above about 500°C.

Composition ranges for 316L stainless steels wire mesh/screen

Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 |

Mechanical properties of 316L stainless steels wire mesh/screen

Grade | Tensile Str (MPa) min | Yield Str 0.2% Proof (MPa) min | Elong (% in 50mm) min | Hardness | |

Rockwell B (HR B) max | Brinell (HB) max | ||||

316L | 485 | 170 | 40 | 95 | 217 |

Physical properties for 316 grade stainless steels.

Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Elec Resistiviy (nΩ.m) | |||

0-100°C | 0-315°C | 0-538°C | At 100°C | At 500°C | |||||

H | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

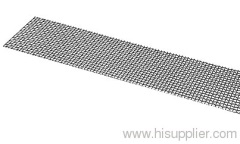

Wire Mesh/screen Specifications:

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Available Wire Mesh weaving forms:

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Available Wire Mesh weaving forms:

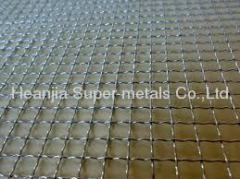

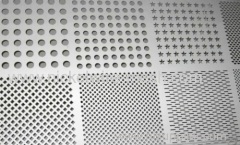

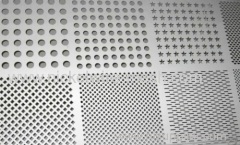

Expanded Mesh |

Perforated Mesh |

Twill Weave mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Dutch Weave Mesh |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Plain Weaving Mesh |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

316 Stainless Steel

Stainless Steel 316

Stainless Steel Wire Netting

Stainless Steel Mesh Screen

Stainless Steel Wire Screen

Stainless Steel Wire Mesh

More>>