|

Heanjia Super-metals Co., Ltd.

|

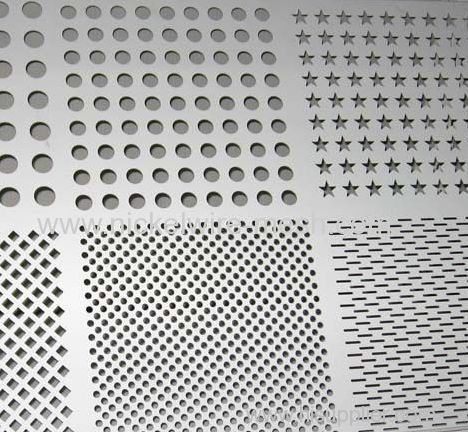

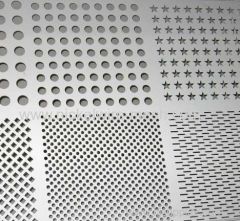

Inconel 625 Perforated Metal

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The Inconel 625 Perforated Metal is utilized for the high potency, superior fabricability and excellent resistance to the various corrosive media.

The Inconel 625 Perforated Metal is utilized for the high potency, superior fabricability and resistance to corrosion. The service temperature varies from cryogenic temperature to 1800oF or 982oC. The combination of molybdenum and niobium with nickel and chromium tends to offer excellent resistance to the various kinds of rigorous corrosive media and high temperature effects like oxidation and carburization.

The features of Inconel 625 Perforated Metal that make it best for using in the sea water operations are its isolation from the local attack like resistance to pitting and crevice corrosion, high fatigue strength, tensile strength and resistance to chloride ion stress corrosion cracking.

Chemical Composition of Inconel 625 Perforated Metal

Alloy | % | Ni | Cr | Mo | Al | Nb | C | Co | Mn | Ti | Si | Fe |

Inconel625 | Min. | 20.0 | 8.0 | 0.80 | 3.15 | |||||||

Max. | 58.0 | 23.0 | 10.0 | 1.50 | 4.15 | 0.1 | 1.0 | 0.50 | 0.40 | 0. 5 | 5.00 |

Mechanical Properties of Inconel 625 Perforated Metal

Item | Annealed | Solution annealed |

Tensile Strength, (Mpa) | 830 | 690 |

Yield Strength (0.2% Offset),(Mpa) | 415 | 275 |

Elongation, % | 30 | 30 |

Characteristics of Inconel 625 Perforated Metal

1. Enormous resistance to corrosion in the variety of corrosive media.

2. High resistance to pitting and crevice corrosion.

3. Vital resistance to corrosion of fresh water, sea water, neutral salts and alkaline media.

Applications of Inconel 625 Perforated Metal

1. Aerospace Components

2. Chemical processing houses

3. Marine applications

4. Power Houses