|

Heanjia Super-metals Co., Ltd.

|

Inconel X-750 Mesh Demister Inconel X-750 Mesh Pad

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Inconel X-750 is a nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300º F.

Inconel X-750 Mesh Demister

Inconel X-750 is a nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300º F.

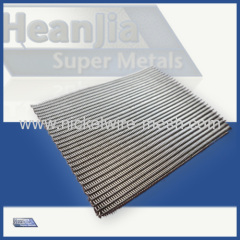

Inconel X-750 Mesh Demister has been widely used in columns, evaporators, liquid-vapor separators, boilers, waste gas processing and compressor outlet for eliminating oil. It gets rid of the shortcomings of the traditional mist eliminators such as narrow operating range, low gas velocity, entrainment. Its operating range is about twice of traditional mist eliminators. The demisting efficiency is up to 100% for droplets of 5um or larger. According to the process, it can be installed in the existing equipment or made a standalone demister.

Technical Data:

Typical Limit Drop sizes = 3 microns

Mesh Pad Velocities = 450 fpm

Typical Mesh Pad pressure drop STP = 0.4w.c.

Mesh Pad + Profile Mist Eliminator Velocity = 1100 fpm

Typical Pressure drop for Mesh Pad + Profile Mist Eliminator combination= 0.6w.c.

Available specifications:

Diameter:1000-4100mm

Thinkness:100-200mm

Filtration rating: 98%-98.9%

Chemical Composition(%)

Alloy | % | Ni | Cr | Fe | Nb | Ti | Co | C | Mn | Si | S | Cu | Al |

Inconel X-750 | Min. | 70 | 14 | 5 | 0.7 | 2.25 | 0.4 | ||||||

Max. | 17 | 9 | 1.2 | 2.75 | 1.0 | 0.08 | 1.0 | 0.5 | 0.01 | 0.5 | 1 |

Physical properties:

Alloy | Density | Melting range |

Inconel X-750 | 8.28 g/cm3 | 1393-1427 |

Preferred applications:

To reduce loss of valuable products

To increase throughout capacity

To improve product purity

To protect compressors

To reduce loss of valuable products

To increase throughout capacity

To improve product purity

To protect compressors

To deal with condensates

To reduce down sream corrosion and fouling

To prevent air or water pollution Features:

High efficiency, wide operation range, easy installing, low cost.

To reduce down sream corrosion and fouling

To prevent air or water pollution Features:

High efficiency, wide operation range, easy installing, low cost.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!