|

Heanjia Super-metals Co., Ltd.

|

Inconel 625 Wire Mesh/ Screen

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Inconel 625 Wire Mesh/ Screen has the best all-round combination of strength and corrosion resistance of the Inconel family of alloys.Mesh 0.5-250mesh

INCONEL625WIRE MESH / SCREEN

Inconel 625 Wire Mesh/ Screen is a nickel chromium molybdenum alloy with high strength at elevated temperatures, combined with outstanding corrosion resistance. It has the best all-round combination of strength and corrosion resistance of the Inconel family of alloys.

Inconel 625 Wire Mesh/ Screen is pre-qualified for use in pressure vessels up to 815℃. It is used from cryogenic temperatures to 980℃. Fatigue strength is outstanding, particularly as the bellows grade.

Corrosion Resistance of Inconel 625 Wire Mesh/ Screen:

Inconel 625 has a corrosion resistance to many environments. In mild environments such as atmosphere, fresh water and sea water, neutral salts and alkaline media there is almost no attack. In more aggressive media nickel and chromium resist oxidizing attack, while nickel and molybdenum resist reducing environments. Molybdenum provides exceptional resistance to pitting and crevice corrosion, and niobium stabilizes against sensitization and intergranular corrosion. The nickel content makes Inconel 625 essentially free from chloride ion stress corrosion cracking. Inconel 625 also has excellent corrosion fatigue properties.

Available specifications of Inconel 625 Wire Mesh/ Screen:

Mesh: 0.5-250mesh, Thickness:0.05mm above

Chemical Composition(%) of Inconel 625 Wire Mesh/ Screen:

Alloy | % | Ni | Cr | Mo | Al | Nb | C | Co | Mn | Ti | Si | Fe |

Inconel 625 | Min. | 20.0 | 8.0 | 0.80 | 3.15 | |||||||

Max. | 58.0 | 23.0 | 10.0 | 1.50 | 4.15 | 0.1 | 1.0 | 0.50 | 0.40 | 0. 5 | 5.00 |

Mechanical Properties of Inconel 625 Wire Mesh/ Screen:

Item | Annealed | Solution annealed |

Tensile Strength, (Mpa) | 830 | 690 |

Yield Strength (0.2% Offset), (Mpa) | 415 | 275 |

Elongation, % | 30 | 30 |

Applications of Inconel 625 Wire Mesh/ Screen:

(1)Aerospace field, used in such applications as aircraft ducting systems, engine

exhaust systems, thrust-reverser systems, resistance-welded honeycomb structures

for housing engine controls, fuel and hydraulic line tubing, spray bars, bellows, turbine shroud rings, and heat-exchanger tubing in environmental control systems.

(2)Chemical plant, bellows, submerged marine components, weld overlays, power station scrubber systems,

(3)General corrosion applications for aggressive environments, combustion and ducting systems, fuel nozzles, after burners, aerospace components.

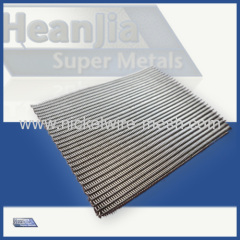

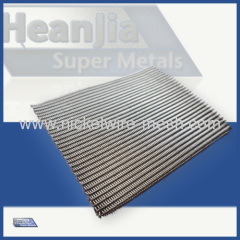

Mesh's Woven Method

Mesh's Woven Method

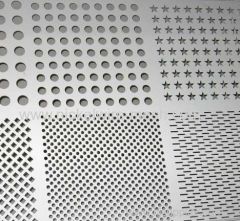

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

The "Service" Part has more information about Mesh Form

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Inconel Alloy Wire

Screen Wire Mesh

Wire Mesh Screen

Screen Printing Wire Mesh

Window Screen Wire Mesh

Metal Wire Mesh Screen

More>>