|

Heanjia Super-metals Co., Ltd.

|

Inconel 783 Wire Mesh Screen Inconel Wire Mesh

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Inconel 783 Wire Mesh/Screen has low coefficient of thermal expansion, high strength and excellent resistance to oxidation.Mesh: 0.5-250 mesh

INCONEL 783 WIRE MESH / SCREEN

Inconel 783 Wire Mesh/Screen is an oxidation resistant low coefficient of thermal expansion (low CTE) superalloy developed for gas turbine applications. Inconel 783 Wire Mesh/Screen is strengthened by a precipitation-hardening heat treatment made possible by additions of niobium and aluminum. In addition, the aluminum content provides excellent resistance to oxidation at high temperature. Inconel 783 Wire's density is 5% less than those of superalloys such as INCONEL alloy 718 wire.

The combination of low expansion, high strength and excellent resistance to oxidation makes Inconel 783 Wire Mesh especially useful for gas turbine and steam turbine components. The low expansion enables closer control of clearances and tolerances for greater power output and fuel efficiency.

To ensure the quality of our product, we can produce the product with raw materials from the international suppliers. Every batch of product can be tracked to the original raw material supplier. We co-operate with international suppliers like Allvac(ATI), Bohler, Carpenter, Dunkirk, Gloria, OttoKumpu, SMC, ThyssenKrupp VDM, Valbruna, etc.

Limiting Chemical Composition*, % of Inconel 783 Wire Mesh:

Chromium...................................................................... 2.5-3.5

Nickel .........................................................................26.0-30.0

Iron ..............................................................................24.0-27.0

Niobium...........................................................................2.5-3.5

Aluminum........................................................................5.0-6.0

Cobalt........................................................................Remainder

Boron.......................................................................0.003-0.012

Carbon........................................................................0.03 max.

Manganese .................................................................0.50 max.

Silicon .........................................................................0.50 max.

Phosphorus..............................................................0.015 max.

Sulfur .........................................................................0.005 max

Titanium...........................................................................0.1-0.4

Copper.........................................................................0.50 max

Physical Properties of Inconel 783 Wire Mesh:

Quantity | Value | Unit |

Thermal expansion | 16 - 17 | e-6/K |

Thermal conductivity | 16 - 16 | W/m.K |

Specific heat | 500 - 500 | J/kg.K |

Melting temperature | 1370 - 1400 | °C |

Service temperature | 0 - 500 | °C |

Density | 8000 - 8000 | kg/m3 |

Resistivity | 0.7 - 0.7 | Ohm.mm2/m |

Mechanical Properties of Inconel 783 Wire Mesh:

Properties | Conditions | ||

T (°C) | Treatment | ||

Density (×1000 kg/m3) | 7.7-8.03 | 25 | |

Poisson's Ratio | 0.27-0.30 | 25 | |

Elastic Modulus (GPa) | 190-210 | 25 | |

Tensile Strength (Mpa) | 1158 | 25 | oil quenched, fine grained, tempered at 425°C |

Yield Strength (Mpa) | 1034 | ||

Elongation (%) | 15 | ||

Reduction in Area (%) | 53 | ||

Hardness (HB) | 335 | 25 | oil quenched, fine grained, tempered at 425°C |

Thermal Properties of Inconel 783 Wire Mesh:

Properties | Conditions | ||

T (°C) | Treatment | ||

Thermal Conductivity (W/m-K) | 42.7 | 100 | |

Specific Heat (J/kg-K) | 477 | 50-100 | |

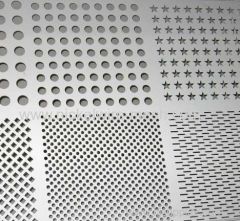

Mesh's Woven Method

Expanded Mesh |

Perforated Mesh |

Twill Weave mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Dutch Weave Mesh |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Plain Weaving Mesh |

Product Description: The product produced by us is of good quality and is priced reasonably.

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Inconel Alloy Wire

Screen Wire Mesh

Wire Mesh Screen

Screen Printing Wire Mesh

Window Screen Wire Mesh

Metal Wire Mesh Screen

More>>