|

Heanjia Super-metals Co., Ltd.

|

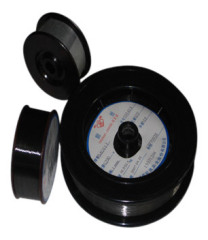

Molybdenum Wire for Linear Cutting VEDM

| Price: | 15.0~30.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Molybdenum wire for linear cutting has high tensile strength, good stability, good electric discharge, low elongation, high wire diameter consistent.

Molybdenum Wire for Cutting

Molybdenum wire for cutting has high tensile strength, good stability, good electric discharge, low elongation, high wire diameter consistent. Molybdenum wire for cutting is not easy to break and has long servicing life. Molybdenum wire cutting can the cut metals in smooth finish, high cutting speed, and high precision. The wire is vacuum packed in order to prevent oxidation.

Molybdenum wire for cutting has high tensile strength, good stability, good electric discharge, low elongation, high wire diameter consistent. Molybdenum wire for cutting is not easy to break and has long servicing life. Molybdenum wire cutting can the cut metals in smooth finish, high cutting speed, and high precision. The wire is vacuum packed in order to prevent oxidation.

Molybdenum wire has outstanding electrical and heat-conducting capabilities and relatively high tensile strength. Thermal conductivity is approximately 50% higher than that of steel, iron or nickel alloys. It consequently finds wide usage as heat sinks. Its electrical conductivity is the highest of all refractory metals, about one third that of copper, but higher than nickel, platinum, or mercury. The coefficient of thermal expansion of molybdenum plots almost linearly with temperature over a wide range. This characteristic, in combination will raise heat-conducting capabilities, accounts for its use in bimetal thermocouples.

Before pressing new moly wire and processing, let the machine run five-ten minutes, the cutting effects will be better.

The Service Part has more information about Wire Further Processing.

Wire Further Processing | Cut to length Wire |

Flat Wire | |

Square and Shaped Wire | |

Rewinding and spooling | |

Polishing and cleaning |

The Service Part has more information about Wire Further Processing.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Molybdenum Wire

Molybdenum Wire Mesh

Spraying Molybdenum Wire

White Molybdenum Wire

Cutting Wire

Molybdenum

More>>