|

Heanjia Super-metals Co., Ltd.

|

Fine Tungsten wires

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

W>99.9%; high melting temperature, low vapor pressure and thermal expansion, good thermal conductivity, sufficient electrical resistance.

Tungsten Wire is the most widely used of the refractory metals. In wire form, it is essential for the production of lighting products such as wire filament, and other goods where its high temperature properties are of use. Among its properties are a melting point of 3410° C, a low coefficient of thermal expansion and low vapor pressure at elevated temperatures, along with good electrical and thermal conductivity.

Pure tungsten wire is produced in sizes above .020 inches in diameter. Typical usage is for restraightening into rod products and for applications where there is a low alkali content requirement.

Tungsten Wire Product Details:

PureTungsten Wire:Purity: W>99.98%

PureTungsten Wire:Purity: W>99.98%

Atomic Number: 74 Atomic Radius: 137.0pm

Atomic Symbol: W Atomic Weight: 183.5

Melting Point: 3422 oC Boiling Point: 5555 oC

Electron Configuration: [Xe]6s24f145d4

Electron Configuration: [Xe]6s24f145d4

Oxidation States: 6

Characteristics:

1) Tungsten is a very hard, dense, silvery-white, lustrous metal that tarnishes in air, forming a protective oxide coating. In powder form tungsten is gray in color.

2) The metal has the highest melting point of all metals, and at temperatures over 1650 oC also has the highest tensile strength. Pure tungsten is ductile, and tungsten wires, even of a very small diameter, have a very high tensile strength.

3) Tungsten is highly resistant to corrosion. It forms tungstic acid (H2WO4), or wolframic acid from the hydrated oxide (WO3) and its salts are called tungstates, or wolframates. Surface finish is supplied

2) The metal has the highest melting point of all metals, and at temperatures over 1650 oC also has the highest tensile strength. Pure tungsten is ductile, and tungsten wires, even of a very small diameter, have a very high tensile strength.

3) Tungsten is highly resistant to corrosion. It forms tungstic acid (H2WO4), or wolframic acid from the hydrated oxide (WO3) and its salts are called tungstates, or wolframates. Surface finish is supplied

1: Black, as drawn condition, where drawing lubricants and oxides are retained on the surface,

2: Cleaned condition by firing in hydrogen or electrochemical etching.

Tungsten wire property:

Tungsten Wire is mainly used as Light Filament. As a high performance materials, Pure Tungsten has high melting temperature, high density, low vapor pressure, low thermal expansion combined with good thermal conductivity, sufficient electrical resistance, high modulus of elasticity.

Tungsten Wire Application:

1) Filaments for lamps of coiled-coil or three-coiled incandescent lamp, fluorescent lamp, halogen lamp, auto lamp and hi-color temperature lamps, etc.

2) For making supports and electron tubes.

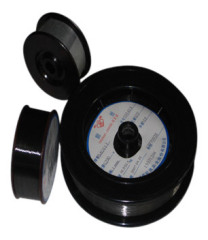

Tungsten wire Spooling

Tungsten wire is spooled on clean, defect free spools. For very large diameters, tungsten wire is self coiled. Spools are level filled without piling near flanges. The outer end of the wire is properly marked and attached securely to the spool or self coil.

We supply:

1: Black tungsten wire: drawing lubricants and oxides are retained on the surface,

2: Cleaned tungsten wire( white tungsten wire): lubricants and oxides be removed by firing in hydrogen or electrochemical etching. we supply electrolytic cleaned wire, hydrogen-sintered cleaned wire,

3: Straightened Tungsten Wire

1: Black tungsten wire: drawing lubricants and oxides are retained on the surface,

2: Cleaned tungsten wire( white tungsten wire): lubricants and oxides be removed by firing in hydrogen or electrochemical etching. we supply electrolytic cleaned wire, hydrogen-sintered cleaned wire,

3: Straightened Tungsten Wire

Wire Further Processing | Cut to length Wire |

Flat Wire | |

Square and Shaped Wire | |

Rewinding and spooling | |

Polishing and cleaning |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!