|

Heanjia Super-metals Co., Ltd.

|

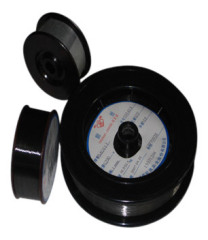

Molybdenum spraying wire

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Molybdenum to spray thermically on surfaces of mechanically strongly stressed automobile parts, such as piston rings, to increase abrasion resistance.

Molybdenum spraying wire is used as a thin coating on the surface of automobile components subjected to wear, such as piston rings, gearbox synchromesh parts, selector forks, etc.

Molybdenum spraying wire is also sprayed onto machine parts such as bearing for repair purposes. Furthermore, molybdenum spray wire is applied as an intermediate layer.

Wire Diameter:0.05mm-10.0mm, 0.002 Inch to 0.3937 Inch

Molybdenum spraying wire is also sprayed onto machine parts such as bearing for repair purposes. Furthermore, molybdenum spray wire is applied as an intermediate layer.

Wire Diameter:0.05mm-10.0mm, 0.002 Inch to 0.3937 Inch

molybdenum has become an indispensable material for metal spraying technology, duo to its high abrasion and wear resistance.Thin layers of molybdenum are sprayed thermically on surfaces of mechanically strongly stressed automobile parts, such as piston rings, synchronizer rings, shift elements, to increase their abrasion resistance.

molybdenum spray wire, furthermore, is applied as an intermediate layer in the case of repairs of machine parts, such as bearing shells and shafts, because of the lacking adhesion of steel layers to steel without intermediate molybdenum layers.

molybdenum spray wire, furthermore, is applied as an intermediate layer in the case of repairs of machine parts, such as bearing shells and shafts, because of the lacking adhesion of steel layers to steel without intermediate molybdenum layers.

Molybdenum Wire - Materials:

pure molybdenum>99.95%; impurities<0.05%, each element content<0.01%.

Molybdenum Wire - Appearance:

Molybdenum spraying wire is covered with graphite. After removed graphite, it is metallic luster.

Molybdenum spraying wire is covered with graphite. After removed graphite, it is metallic luster.

Molybdenum spraying wire Properties:

The weight of single wire is up to 20-25kg without any welded joint, which results in enhancing the efficiency and decreasing the operating costs.

Molybdenum Spraying Wire - Features:

Very good interlaminar strength at strong thermal and mechanical loadings.

Wire Further Processing | Cut to length Wire |

Flat Wire | |

Square and Shaped Wire | |

Rewinding and spooling | |

Polishing and cleaning |

The Service Part has more information about Wire Further Processing.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Spraying Molybdenum Wire

Molybdenum Wire

Spraying Metal Wire

Molybdenum Wire Mesh

White Molybdenum Wire

Molybdenum

More>>