|

Heanjia Super-metals Co., Ltd.

|

Resistance Wires

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Resistance Wires: Fe-Cr-Al wire, Nichrome Wires: resistivity stable, good mechanical property in high temperature. Long service life.

Resistance Wire

There are two kinds of resistane wires: Nichrome resistance wire and FeCrAl alloy resistance wire. They are they are widely used in water heater, furnace, electric heaters, floor heating and other heating elements. The two material series have their different advantages.

Nichrome Resistance Wire:

Nichrome Resistance Wire is corrosion resistant, and has a high melting point of about 1400 °C (2552 °F). It has relatively high resistivity and very good resistance to oxidation at high temperatures. The ultimate tensile strength of Nichrome Resistance Wire is 105,000 PSI (Pounds per Square Inch), yield strength is around 50,000 PSI, and modulus of elasticity is 31 x 106 PSI.Nichrome Resistance Wire Applications:

Nichrome Resistance Wires have many advantages, such as deformation ability, thermal stability, mechanical character, shockproof ability in thermal state and anti-oxidization. For heating, Resistance Wire must be stable in air when hot. The wire forms a protective layer of chromium oxide. Due to its relatively high resistivity and resistance to oxidation at high temperatures.

Nichrome Resistance Wire is widely used in heating elements, electric furnace heating and heat-treating processes in the chemical, mechanical, metallurgical and defense industries, such as in hair dryers, electric ovens, toasters, vacuum coating, inner components of vacuum valves, etching resistor, brake resistor, tube heater, sealer, boiler and even electronic cigarettes.

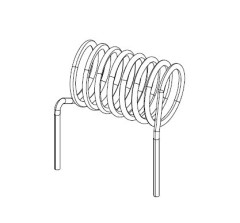

Nichrome Resistance Wire is wound in coils to a certain electrical resistance, and current passed through to produce heat. They are also used as material of industrial equipment and electrical resistant elements in the electronics and light textile industries.

Nichrome Resistance Wire is an ideal material, because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time. Material beneath the Resistance Wire will not oxidize, preventing the Resistance Wire from breaking or burning out. So it is good for anti-corrosion and high resistant co-efficiency.

Nichrome Resistance Wire is applicable for heat treatment, air-carbon furnace, chemical industry, machinery, metallurgy. It is commonly used in ceramics as an internal support structure to help some elements of clay sculptures hold their shape while they are still soft.The Wire's metallurgical structure confers them a very good plasticity when cold. There is a growth of the grain under heat during utilization of the element without inducing embrittlement of it when cold.

Nichrome Resistance Wires are used for the manufacture of electric resistances for appliances (insulated elements type tubular resistances or for example opened elements on micanit plate) or for application of industrial furnaces. In addition of a relatively high specific resistance, Ni-Cr alloys join all the necessary properties for good performances in use of furnaces: Resistance to oxidation (they are not sensitive to aggressions of humid air). Low embrittlement at high temperature Good plasticity – Easier to give them a shape compared with Fe Cr Al (lower mechanical characteristics allow indeed a good control of elasticity of the product during shaping (coiling, folding, drawing). Good resistance to creeping (more important than ferritic alloys) which is important during conception of a resistance presenting big heights of waves. Maximal temperature recommended in the furnace: 1922 / 2012 °F in order to obtain a reasonable life time of the elements.

Nichrome Resistance Wire is widely used in heating elements, electric furnace heating and heat-treating processes in the chemical, mechanical, metallurgical and defense industries, such as in hair dryers, electric ovens, toasters, vacuum coating, inner components of vacuum valves, etching resistor, brake resistor, tube heater, sealer, boiler and even electronic cigarettes.

Nichrome Resistance Wire is wound in coils to a certain electrical resistance, and current passed through to produce heat. They are also used as material of industrial equipment and electrical resistant elements in the electronics and light textile industries.

Nichrome Resistance Wire is an ideal material, because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time. Material beneath the Resistance Wire will not oxidize, preventing the Resistance Wire from breaking or burning out. So it is good for anti-corrosion and high resistant co-efficiency.

Nichrome Resistance Wire is applicable for heat treatment, air-carbon furnace, chemical industry, machinery, metallurgy. It is commonly used in ceramics as an internal support structure to help some elements of clay sculptures hold their shape while they are still soft.The Wire's metallurgical structure confers them a very good plasticity when cold. There is a growth of the grain under heat during utilization of the element without inducing embrittlement of it when cold.

Nichrome Resistance Wires are used for the manufacture of electric resistances for appliances (insulated elements type tubular resistances or for example opened elements on micanit plate) or for application of industrial furnaces. In addition of a relatively high specific resistance, Ni-Cr alloys join all the necessary properties for good performances in use of furnaces: Resistance to oxidation (they are not sensitive to aggressions of humid air). Low embrittlement at high temperature Good plasticity – Easier to give them a shape compared with Fe Cr Al (lower mechanical characteristics allow indeed a good control of elasticity of the product during shaping (coiling, folding, drawing). Good resistance to creeping (more important than ferritic alloys) which is important during conception of a resistance presenting big heights of waves. Maximal temperature recommended in the furnace: 1922 / 2012 °F in order to obtain a reasonable life time of the elements.

FeCrAl Alloy Resistance Wire:

FeCrAl Resistance Wire has high resistance, low temperature coefficient of electric resistance, high operating temperature, and good corrosion resistance under high temperature, especially under the atmosphere containing sulfides. It possesses good oxidation and heat resistance.This kind of resistance wire is creep-resistant over a wide range of temperature, which is another of their important qualities.

FeCrAl Resistance Wire has several potential advantages, such as lower raw-material cost, superior oxidation resistance, lower density, and lower thermal expansion coefficient than the Ni-base super-alloys.FeCrAl Resistance Wire has less hot strength than nickel s but much higher melting point and lower price. After being heated the Resistance Wire's plasticity becomes bad, easy brittleness, not to be easy to weld. However, If can be reasonably used, also be a kind of ideal electric heating material.

FeCrAl Resistance Wire has several potential advantages, such as lower raw-material cost, superior oxidation resistance, lower density, and lower thermal expansion coefficient than the Ni-base super-alloys.FeCrAl Resistance Wire has less hot strength than nickel s but much higher melting point and lower price. After being heated the Resistance Wire's plasticity becomes bad, easy brittleness, not to be easy to weld. However, If can be reasonably used, also be a kind of ideal electric heating material.

FeCrAl Resistance Wires are made of iron chromium aluminum base s containing small amounts of reactive elements such as yttrium and zirconium. The high aluminum content, in combination with the high chromium content causes the scaling temperature to increase up to 1425 C (2600F ); Fe Cr Al Resistance Resistance Wire s also have excellent oxidation properties at 800-1300° C because of the formation of a highly protective Al2O3 scale.

FeCrAl Resistance Wire Applications:

FeCrAl Resistance Wire intended for prolonged operation at high temperature. It isused chiefly for heating elements in the electrical industry and wide range of high-temperature oxidation environments, such as industrial electric furnace, heating furnace, nuclear reactor, petroleum refinery and automotive exhaust system, household electrical appliance, electrical oven, electrical heater, infrared settings and far infrared ray device. Because ofFeCrAl Resistance Wire' ability to withstand oxidation, the it can be employed under high-temperature conditions, while their good ductility enables them to be processed into Resistance Wire and Resistance Wire by hot and cold working.

Available Specifications In Xinxing Nickel Wire Mesh Factory:

Wire Diameter:0.05mm-10.0mm, 0.002 Inch to 0.3937 Inch

Available Specifications In Xinxing Nickel Wire Mesh Factory:

Wire Diameter:0.05mm-10.0mm, 0.002 Inch to 0.3937 Inch

The attached file is detailed description of other Nickel chromium alloy Resistance wire and Fe- Cr Al Resistance wire physical properties.

Wire Further Processing | Cut to length Wire |

Flat Wire | |

Square and Shaped Wire | |

Rewinding and spooling | |

Polishing and cleaning |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!