|

Heanjia Super-metals Co., Ltd.

|

Monel Wire Mesh Screen

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Monel Wire Mesh/Screen:Monel 400 and monel K500: Resistant to sea water,steam; to salt and caustic solutions even at high temperature.

MONELWIREMESH / SCREEN

Monel is a kind of nickel alloy. It has high strength and excellent corrosion resistance in a range of acidic and alkaline sitrations and especially sutiable for reducing conditions. It also has good ductility and thermal conductivity. Monel Wire Mesh/Screen includes two kinds of material: Monel 400 and Monel K500. Each of them has their unique and outstanding properties.

Monel 400 alloy wire Mesh/Screen is corrosion resisting, such as resistant to sea water and steam at high temperatures, resistant to salt and caustic solutions. Meanwhile, Monel 400 mesh exhibits characteristic like high strength. Monel 400 wire mesh has low corrosion rate in flowing brackish or seawater while performing excellent resistance to stress-corrosion cracking in most freshwaters. This mesh's good resistance to a variety of corrosive conditions contributes to the wide application in marine and other non-oxidizing chloride solutions.

Monel is a kind of nickel alloy. It has high strength and excellent corrosion resistance in a range of acidic and alkaline sitrations and especially sutiable for reducing conditions. It also has good ductility and thermal conductivity. Monel Wire Mesh/Screen includes two kinds of material: Monel 400 and Monel K500. Each of them has their unique and outstanding properties.

Monel 400 alloy wire Mesh/Screen is corrosion resisting, such as resistant to sea water and steam at high temperatures, resistant to salt and caustic solutions. Meanwhile, Monel 400 mesh exhibits characteristic like high strength. Monel 400 wire mesh has low corrosion rate in flowing brackish or seawater while performing excellent resistance to stress-corrosion cracking in most freshwaters. This mesh's good resistance to a variety of corrosive conditions contributes to the wide application in marine and other non-oxidizing chloride solutions.

Monel 400 wire mesh/screen is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. However, its high copper content, make alloy 400 can be rapidly attacked by nitric acid and ammonia systems.Monel 400 wire mesh also has good Adaptability to wide range of application temperature. It maintains good mechanical properties at subzero temperatures, as well as in temperatures up to 1000° F, The melting point is 2370-2460° F.

Manufacture's Objective Comments:

Monel 400 wire mesh/screen is immune to chloride ion stress corrosion cracking in typical environments. Besides, it is good corrosion resistant in reducing environments, but poor in oxidizing conditions. It is not useful in oxidizing acids, such as nitric acid and nitrous. Monel 400 Mesh would be attacked in sulfur-bearing gases above approximately 700° F and molten sulfur attacks the alloy at temperatures over approximately 500° F. However, it is resistant to most alkalis, salts, waters, food products, organic substances and atmospheric conditions at normal and elevated temperatures.

Monel 400 mesh/screen offers about the same corrosion resistance as nickel but with higher maximum working pressures and temperatures and at a lower cost due to its superior ability to be machined.

Applications of Monel 400 Alloy Wire Mesh / Screen:

Marine engineering | Chemical and hydrocarbon processing equipment |

Gasoline and freshwater tank | Crude petroleum stills |

De-aerating heaters | Boiler feed water heaters and other heat exchangers |

Industrial heat exchangers | Crude oil distillation towers |

Chlorinated solvents | Valves, pumps, shafts, fittings, and fasteners |

Monel 400 wire mesh/screen Chemical composition (%) | ||||||

C | Mn | S | Si | Ni | Cu | Fe |

.30 max | 2.00 max | .024 max | .50 max | 63.0 min | 28.0-34.0 | 2.50 max |

Monel K-500 wire Mesh/Alloy K500 wire mesh/screen

Monel K500 wire Mesh/screen is one kind of the nickel-copper alloy mesh. Monel K500 wire mesh combines the excellent corrosion resistance of Monel 400 Mesh with the added advantage of greater strength and hardness. Alloy K-500 wire Mesh has approximately three times the yield strength and double the tensile strength when compared with alloy 400. When in the age-hardened condition.

Monel K-500 wire Mesh/Screen has a greater tendency toward stress-corrosion cracking in some conditions than Monel 400 alloy Mesh. The strength of this nickel Copper alloy is maintained to 1200° F but stays ductile and tough down to temperatures of 400° F. Its melting range is 2400-2460° F. Nickel alloy K-500 Mesh has a greater tendency toward stress-corrosion cracking in some environments.

Monel K-500 wire Mesh/Screen is resistant to a sour-gas environment. The combined Characteristics of very low corrosion rates in high-velocity sear water and high strength make alloy K-500 mesh particularly suitable for marine service. In stagnant or slow-moving sea water, fouling may occur followed by pitting but this pitting slows down after a fairly rapid initial attack.

Manufacture's Advices to Monel K-500 alloy wire Mesh:

This nickel alloy is spark resistant and non-magnetic to -200° F. However, it is possible to develop a magnetic layer on the surface of the material during processing. Aluminum and copper may be selectively oxidized during heating, leaving a magnetic nickel rich film on the outside. Pickling or bright dipping in acid can remove this magnetic film and restore the non-magnetic properties.

Monel K-500 wire mesh/Screen applications:

Sour-gas service applications | Oil and gas production safety lifts and valves |

Oil-well tools and instruments | Oil well industry |

Monel K 500 Chemical Composition, %

Ni | Cu | Al | Ti | C | Mn | Fe | S | Si |

63.0-70.0 | Remainder | 2.30-3.15 | .35-.85 | .25 max | 1.5 max | 2.0 max | .01 max | .50 max |

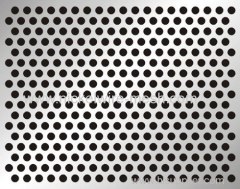

Mesh Weaving Method

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

The Service Part has more information about mesh form.

Product Description: The product produced by us is of good quality and is priced reasonably.

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Monel Alloy Wire Mesh

Monel Wire Cloth

Screen Wire Mesh

Wire Mesh Screen

Screen Printing Wire Mesh

Window Screen Wire Mesh

More>>