|

Heanjia Super-metals Co., Ltd.

|

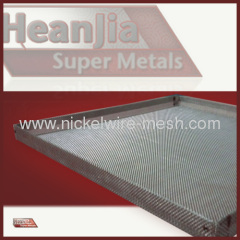

FeCrAl Wire Meshes

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

FeCrAl Mesh/Screen: Twilled Woven:high resistance, excellent oxidation properties high operating temperature; much higher melting point, lower price.

Fe Cr Al Wire Mesh/Screen

FeCrAl Wie Mesh/Screen have high resistance, low temperature coefficient of electric resistance, high operating temperature, and good corrosion resistance under high temperature, especially under the atmosphere containing and/or sulfides. FeCrAl wire Mesh/Screen has less hot strength than nickel alloys but much higher melting point and lower price. After being heated the alloy's plasticity becomes bad, easy brittleness, not to be easy to weld. However, If can be reasonably used, they also be a kind of ideal electric heating material. To ensure the quality of these very fine wires, the best materials and strict quality controll system were applied.

FeCrAl Wire Mesh/Screen are made of iron chromium aluminum base alloys containing small amounts of reactive elements such as yttrium and zirconium. The high aluminum content, in combination with the high chromium content causes the scaling temperature to increase up to 1425 C (2600F ); Fe Cr Al alloy wires also have excellent oxidation properties at 800-1300° C because of the formation of a highly protective Al2O3 scale.

FeCrAl wire Mesh/Screen are used in many applications, Such as industrial electric furnace, household electrical appliance, electrical oven, electrical heater, infrared settings and far infrared ray device.

Twilled Weaving:

Twilled Weaving:

Contrary to plain weave, two lines of the main and cross wires are interweaved alternately.Each weft wire passes over two and under two warp wires, and each warp wire passes over and under two weft wires. The wire diameter for both (warp and weft)is mostly the same. It is possible to use a wire thicker than the mesh of twilled weave and, it has an advantage of vulcanization being small because the angle of refraction of the main and cross wires is big. It is suitable for cases of comparatively high or much load.

The available specifications from our factory are:

Mesh: 0.5-250 mesh/InchThickness: Min0.05mm

Mesh Weaving Method

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Please see the following chart about FeCrAl Wire Mesh's properties:

Type | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

Maximal Temperature (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

Resistivity 20oC (10-6ohm*m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

Thermal conductivity (KJ/m*h*oC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

Extend strength (a*10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

Melting point ( oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

Percentage elongation (%)) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

Section shrink rate(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

curve strength(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

Microstructure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

Magnetism | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Anping Wire Meshes

Reinforcement Meshes

Brass Metal Meshes

Vibrating Screen Meshes

Wire Mesh

Steel Wire

More>>