|

Heanjia Super-metals Co., Ltd.

|

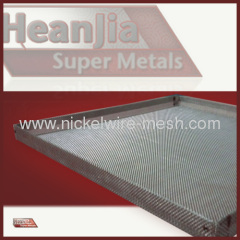

FeCrAl 0Cr27Al7Mo2 Gas Furnace Wire Mesh

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

H23YU5(0Cr23Al5) is widely used in household lectrical appliance,heating elements,mechanical manufacturing and other industrial fields.

FeCrAl 0Cr27Al7Mo2 Gas Furnace Wire Mesh

Heanjia Super-metals Co., Ltd. supplies FeCrAl 0Cr27Al7Mo2 Gas Furnace Wire Mesh. FeCrAl 0Cr27Al7Mo2 Gas Furnace Wire Mesh is iron-chromium-aluminium alloy Mesh which is recommended for use at Mesh temperatures up to 1400°C Max., can replace Kanthal series. In addition to industrial furnaces, it is used in appliances where its high resistivity and good oxidation resistance are of particular importance.

Chemical Composition

Alloy | Cr% | Al% | Fe% | Re% | Mo% |

0Cr27Al7Mo2 | 26.5-27.8 | 6.0-7.0 | Bal. | Adequacy | 1.8-2.2 |

Properties

Alloy | Specific Resistance (at 20°C) (µΩ-m) | Hardness HB | Linear Expansion Coeff. (T=20 – 1000°C) x10-6 | Maximum Operating Temperature of Element (°C) |

0Cr27Al7Mo2 | 1.53±0.07 | 200-260 | 16.0 | 1400 |

Mesh Specification

Wire Mesh | GB/T 5330.1 ; GB/T 17492 ; JB/T 9155 | 0.5-250 mesh/Inch; Thickness: Min0.05mm |

The manufacture of mesh is started with producing wire. The wire production includes: forging, rolling, annealing and drawing. The wire with right material and wire diameter will be produced. Then the warp wires will be put and prepared on the weaving machine, and then start weaving. From wire to mesh, manufacture process is operated with high standard quality control system. There will be quality test for each batch of product, such as test to diameter tolerance, content, mesh aperture, etc.

Packing Process & Transportation

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air or By sea

Other Terms

Minimum Order Quantity | Manufacture Period | Payment Terms | |

100 KG | 10-15 Days (Small Quantity) | 20-40 Days (Mass Quantity) | L/C, T/T, Western Union |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Gas Water Furnace

Furnace

Gas Filter Mesh

Gas Liquid Filter Mesh

Liquid Gas Filter Mesh

Gas Liquid Mesh

More>>