|

Heanjia Super-metals Co., Ltd.

|

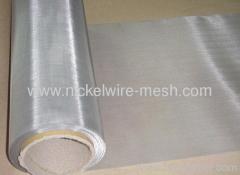

Molybdenum Wire Mesh Screen

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Molybdenum Wire Mesh Screen: Excellent conductivity of electricity, high melting point, high oxidation and erosion resistance.

Molybdenum Wire Mesh

Molybdenum Wire Mesh/Screen Material: Pure Molybdenum Wire

Molybdenum Wire Mesh/Screen Feacture:

Molybdenum wire mesh/screen has outstanding electrical and heat-conducting capabilities and relatively high tensile strength. Thermal conductivity is approximately 50% higher than that of steel, iron or nickel alloys. It consequently finds wide usage as heat sinks. Its electrical conductivity is the highest of all refractory metals, about one third that of copper, but higher than nickel, platinum, or mercury. The coefficient of thermal expansion of molybdenum plots almost linearly with temperature over a wide range. This characteristic, in combination will raise heat-conducting capabilities, accounts for its use in bimetal thermocouples.

Pure molybdenum wire mesh/screen has good resistance to hydrochloric acid and is used for acid service in chemical process industries.

Molybdenum Wire Mesh/Screen Application:

high temperature resistive situation;

Electric vacuum vocation, nuclear, chemical, glass, and metalizing industries. etc.

Available models:

Mesh: 0.5-250 mesh/Inch Thickness: Min0.05mm

Mesh Weaving Method

Molybdenum Wire Mesh/Screen Material: Pure Molybdenum Wire

Molybdenum Wire Mesh/Screen Feacture:

Molybdenum wire mesh/screen has outstanding electrical and heat-conducting capabilities and relatively high tensile strength. Thermal conductivity is approximately 50% higher than that of steel, iron or nickel alloys. It consequently finds wide usage as heat sinks. Its electrical conductivity is the highest of all refractory metals, about one third that of copper, but higher than nickel, platinum, or mercury. The coefficient of thermal expansion of molybdenum plots almost linearly with temperature over a wide range. This characteristic, in combination will raise heat-conducting capabilities, accounts for its use in bimetal thermocouples.

Pure molybdenum wire mesh/screen has good resistance to hydrochloric acid and is used for acid service in chemical process industries.

Molybdenum Wire Mesh/Screen Application:

high temperature resistive situation;

Electric vacuum vocation, nuclear, chemical, glass, and metalizing industries. etc.

Available models:

Mesh: 0.5-250 mesh/Inch Thickness: Min0.05mm

Mesh Weaving Method

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

The Service Part has more information about mesh form.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Molybdenum Wire Mesh

Molybdenum Wire

Screen Wire Mesh

Wire Mesh Screen

Screen Printing Wire Mesh

Window Screen Wire Mesh

More>>