|

Heanjia Super-metals Co., Ltd.

|

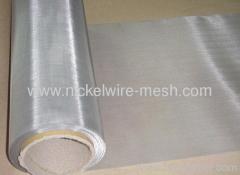

Pure Tungsten Wire Mesh

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Tungsten Wire Mesh: Purity >99.9%, mesh thickness from 0.06mm to 4.0mm, high tensile strength and high melting point. Mesh finished in high quality.

Tungsten Wire Mesh/Screen Characteristics:

The tungsten wire mesh/screen we produced is made of tungsten wire with purity over 99.9%. Tungsten wire mesh/screen has very high tensile strength. It has the highest melting point of all metals even at high temperature over 1650oC. Meanwhile, tungsten wire mesh is highly resistant to corrosion, it has high density,sufficient electrical resistance, high modulus of elasticity low vapor pressure and low thermal expansion combined with good thermal conductivity.

The tungsten wire mesh/screen we produced is made of tungsten wire with purity over 99.9%. Tungsten wire mesh/screen has very high tensile strength. It has the highest melting point of all metals even at high temperature over 1650oC. Meanwhile, tungsten wire mesh is highly resistant to corrosion, it has high density,sufficient electrical resistance, high modulus of elasticity low vapor pressure and low thermal expansion combined with good thermal conductivity.

- High mechanical and thermal stability

- Excellent uniformity

- Low creep deformation

- High surface loading

- Exact resistance

- Long life times

The manufaturing of tungsten wire mesh/screen has two process:

1: Tungsten wire drawing: itis accomplished by coating the wire with a graphite lubricant, heating to a red heat, and then drawing through tungsten carbide or diamond dies. The process is sometimes referred to as hot cold-working, which means that, while the wire is hot, the temperature is still below the recrystallization range. The raw material is qualified with high purity other good metallurgical properties.

The manufaturing of tungsten wire mesh/screen has two process:

1: Tungsten wire drawing: itis accomplished by coating the wire with a graphite lubricant, heating to a red heat, and then drawing through tungsten carbide or diamond dies. The process is sometimes referred to as hot cold-working, which means that, while the wire is hot, the temperature is still below the recrystallization range. The raw material is qualified with high purity other good metallurgical properties.

2: Tungsten wire mesh weaving: the tungsten wire's diameter can be from 0.03mm to 2.0mm according to customer's requirement, meanwhile, the mesh can be from 0.2mesh/inch to 200mesh/inch. The tungsten wire mesh is finished with high quality, such as precised aperture size, mesh thickness, no defect on mesh surface, etc.

Tungsten wire mesh/Screen Specifications:

Thickness: from 0.06mm to 4.0mm,

Mesh density: from 0.2mesh/inch to 200 mesh/inch.

All meshes will be made according to your specified requirements.

Mesh Weaving Method

Tungsten wire mesh/Screen Specifications:

Thickness: from 0.06mm to 4.0mm,

Mesh density: from 0.2mesh/inch to 200 mesh/inch.

All meshes will be made according to your specified requirements.

Mesh Weaving Method

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Pure Nickel Wire Mesh

Pure Tungsten

Pure Tungsten Electrode

Tungsten Wire

Pure Silver Mesh

Black Tungsten Wire

More>>