|

Heanjia Super-metals Co., Ltd.

|

Nickel Wire Ni30Fe Wire Mesh

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

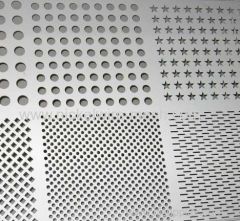

Ni30Fe wire mesh/screen is Nickel-Iron alloy that is used for applications where magnetic shunts are used for temperature compensation in speedometer

Ni30Fe wire mesh/screen

Ni30Fe wire mesh/screen is a Nickel-Iron alloy that is used for applications where magnetic shunts are used for temperature compensation. Most frequently Ni30Fe wire mesh/screen is used for temperature compensation in energy meters, speedometers and temperature regulation devices. Even after very high variations in temperature, no changes have been found in the magnetic properties of these alloys.

To ensure the quality of our product, we can produce the product with raw materials from the international suppliers. Every batch of product can be tracked to the original raw material supplier. We co-operate with international suppliers like Allvac(ATI), Bohler, Carpenter, Dunkirk, Gloria, OttoKumpu, SMC, ThyssenKrupp VDM, Valbruna, etc.

Mesh: 0.5-250 mesh.

Typical Chemistry (Wt.%) of Ni30Fe wire mesh:

Alloy | Manganese | Iron | |

Ni30Fe | 30 | Max 1.0 | Bal |

Typical Physical Properties of Ni30Fe wire mesh:

Alloy | Density | Curie Temperature | Electrical Resistivity | Yongs Modulus (E) | Rigidity Modulus (G) |

Ni30Fe | 8.19 gm/cm³ | 148°C | 80 μΩ-cm | 206.0 kN/ mm2 | 75.6 kN/ mm2 |

Tensile strength Rm | Solution Annealed | Spring Temper & Aged |

Metric | 683 N/mm2 | 850-1200 N/mm2 |

Imperial | 100 Ksi | 123-174 Ksi |

Magnetic properties of Ni30Fe wire mesh:

Difference in magnetization at different temp. At 100 Oe or 8000 Amp. Per Meter field strength. | B-12.5 – B0 > 60mT B0 – B25 > 120mT B25 < 300mT B25 – B50 > 100mT B50 > 40mT |

Recommended Service Temperatures:

Minimum:-200°C (-328°F) but below –120°C (-184°F) slight magnetism may occur.

Maximum:340°C (644°F) for continuous operation. Can be taken up to 1000°C.

Maximum:340°C (644°F) for continuous operation. Can be taken up to 1000°C.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Nickel Wire Mesh

Nickel Woven Wire Mesh

Pure Nickel Wire Mesh

Nickel Chromium Wire Mesh

Nickel Wire

Nickel Coated Wire

More>>