|

Heanjia Super-metals Co., Ltd.

|

Ni-Span-C Alloy 902 Mesh /Screen

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Alloy 902 Mesh:nickel-iron-chromium alloy made precipitation hardenable by additions of aluminum & titanium.Mesh: 0.5-250mesh.

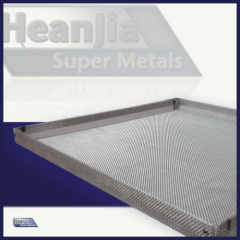

Alloy 902 Wire Mesh /Screen

Ni-Span-C Alloy 902 Wire mesh is a nickel-iron-chromium alloy made precipitation hardenable by additions of aluminum and titanium. The titanium content also helps provide a controllable thermoelastic coefficient, which is the alloy's outstanding characteristic.

Ni-Span-C Alloy 902 wire mesh can be processed to have a constant modulus of elasticity at temperatures from –50 to 150°F (– 45 to 65°C). Used for precision springs,

mechanical resonators, and other precision elastic components.

Mesh: 0.5-250mesh, Thickness:0.05mm above

Typical Chemistry (Wt.%) of Alloy 902 Wire Mesh:

Mesh: 0.5-250mesh, Thickness:0.05mm above

Typical Chemistry (Wt.%) of Alloy 902 Wire Mesh:

Alloy | Ni | Cr | Ti | Fe |

Alloy902 | 41 - 43.5 | 4.9 - 5.75 | 2.2 - 2.75 | 48 |

Typical Properties of Alloy 902 Wire Mesh:

Property | Metric | Imperial |

Density | 8.05 g/cm3 | 0.291 lb/in3 |

Melting point | 1480 °C | 2700 °F |

Co-Efficient of Expansion | 7.6 μm/m.°C (20-100°C) | 4.2x10-6 in/.°F (70-212°F) |

Modulus of rigidity | 62 - 69 kN/mm2 | 8993 - 10008 ksi |

Modulus of elasticity | 165 - 200 kN/mm2 | 23932 - 29008 ksi |

Typical Mechanical Properties Alloy 902 Mesh:

Condition | Approx Tensile Strength | Approx Service Temp | ||

N/mm2 | ksi | °C | °F | |

Annealed | 450 - 650 | 65 - 94 | -45 to +65 | -50 to +150 |

Spring Temper | 900 - 1100 | 131 - 159 | -45 to +65 | -50 to +150 |

Spring Temper Aged | 1300 - 1500 | 189 - 218 | -45 to +65 | -50 to +150 |

Applications:

Springs in precise applications, such as watches and weighing machines.

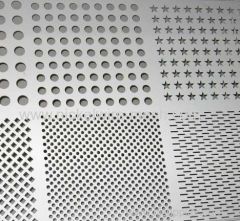

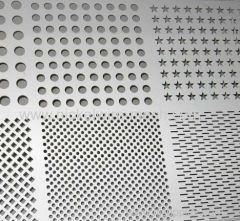

Mesh Weaving Method

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

Competitive price: The labour cost and cost on procuring the raw materials is low and hence the manufacturing cost is reasonable. We provide high facility in short producing cycle and have strong adaptive capacity in producing variation of products.

High quality assured: The work done by us has a good command of advanced technological process in the respect of smelting, rolling, drawing and heat treatment up to finished products. The chemical analysis department, the physical testing department and the quality control department all operate an all-round monitoring of our products from raw materials to final products.

Packing Process & Transportation:

Packaging: Seal up, with plastic inside and wooden case or carton outside; or according to the customer's requirements.

Transportation: By air: Beijing International Airport OR By sea: Trianjin Seaport

We provide our customers with excellent services. If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Alloy Mesh

Mesh Screen

Screen Mesh

Alloy Window Screen

Aluminum Alloy Insect Screen

Alloy Wire Mesh

More>>