|

Heanjia Super-metals Co., Ltd.

|

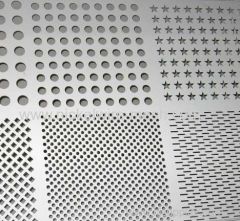

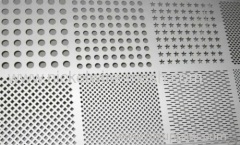

Incoloy 800HT Perforated Metal

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The Incoloy 800HT Perforated Metal is made to explore their high temperature tendencies provides elevated temperature strength and resistance to creep

The Incoloy 800HT Perforated Metal is made to explore their high temperature tendencies. The concentration of carbon of incoloy alloys provides the elevated temperature strength and resistance to creep and cracking. The Incoloy 800HT Perforated Metal has significantly higher tensile characteristics at elevated temperatures up to 2000oF or 1095oC.

The Incoloy 800HT Perforated Metal are widely used in the industrial heating systems. In the different kinds of heating furnaces, these alloys are utilized in the radiant tubes, muffles, retorts, and assorted furnace fixtures. Moreover power production plants use these alloys in the steam superheating tubing and elevated temperature heat exchangers in gas-quenched nuclear reactors.

Physical properties of Incoloy 800HT Perforated Metal are presented below:

Resistance ability of Incoloy 800HT Perforated Metal:

Applications of Incoloy 800HT Perforated Metal:

The Incoloy 800HT Perforated Metal are widely used in the industrial heating systems. In the different kinds of heating furnaces, these alloys are utilized in the radiant tubes, muffles, retorts, and assorted furnace fixtures. Moreover power production plants use these alloys in the steam superheating tubing and elevated temperature heat exchangers in gas-quenched nuclear reactors.

Physical properties of Incoloy 800HT Perforated Metal are presented below:

Densityg/cm3 | 7.94 |

MeltingRange | 2475-2525oFor 1357-1385oC |

SpecificHeat | 460J/kg•°C |

Permeabilityat 70°F (21°C), Annealed | 1.014 |

CurieTemperature | -175oFor -115oC |

Resistance ability of Incoloy 800HT Perforated Metal:

1.Carburization and sulphidation

2.Nitridation

3.Chloride stress corrosion cracking and inter - granularcorrosion

4.Sea water and acids

5.Oxidizing and Non—Oxidizing salts

Applications of Incoloy 800HT Perforated Metal:

1.Production components of baskets, trays and fixtures

2.Heat Exchangers and piping

3.Steam generator tubing in the nuclear power houses

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Perforated Metal

Perforated Metal Sheet

Perforated Metal Mesh

Galvanized Perforated Metal

Galvanized Perforated Metal Mesh

Brass Perforated Metal

More>>