|

Heanjia Super-metals Co., Ltd.

|

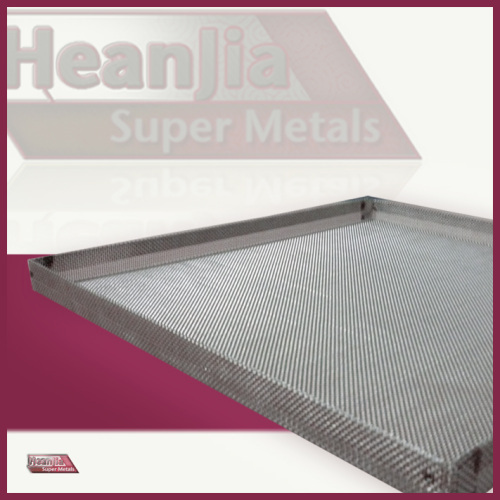

Hastelloy B mesh Screen Hastelloy meshs

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hastelloy B alloy wire mesh screen contains Cr, Mo, It has the ability to resistant oxidation and corrosion .Its melting point is 1330-1370 ℃.

Hastelloy B Mesh/Screen is capable of withstanding high temperature, stress, severe corrosion and erosion prone environment, Hastelloy B Mesh were found extensively usage in nuclear and chemical reactors, pipes and valves in diverse chemical industries. The predominant ingredient used in our Hastlealloy B Mesh/Screen is high grade metal Nickel. The other grades that we offer our clients are Hastelloy C Mesh and Hastelloy X Mesh. follows are main introductions of Hastelloy X Mesh.

Mesh: 0.5-250 mesh/Inch Thickness: Min0.05mm

Mesh: 0.5-250 mesh/Inch Thickness: Min0.05mm

Hastelloy B Mesh/Screen Characteristic:

·Control of iron and chromium content to a minimum to prevent the generation of β-phase Ni4Mo.

·Excellent corrosion resistance of restore environment.

·An excellent resist to concentration sulfuric acid medium and large number of non-oxidizing acid corrosion.

·A very good resistance of chloride reduction of stress corrosion cracking (SCC).

·Good corrosion resistance of various organic acids.

Metallurgical structure:

Hastelloy B Mesh is the face-centered cubic lattice structure. By controlling the content of iron and chromium at the minimum to reduce the processing brittle, prevent Ni4Mo precipitation during 1330-1380 ℃.

Hastelloy B Mesh is the face-centered cubic lattice structure. By controlling the content of iron and chromium at the minimum to reduce the processing brittle, prevent Ni4Mo precipitation during 1330-1380 ℃.

Hastelloy B Mesh/Screen Corrosion resistance:

Ni-Mo alloy Hastelloy B Mesh, the carbon and silicon content is extremely low, reducing the HAZ carbon and other impurities precipitation, so the weld has sufficient corrosion resistance. Alloy Hastelloy B Mesh in the reduction of medium with very good corrosion resistance, such as a various temperature and concentration of hydrochloric acid. In the middle of the concentration of sulfuric acid solution (or contain a certain amount of chloride ions) also has very good corrosion resistance. At the same time can be used to acetic acid and phosphoric acid environment. Alloy material suitable only in the metallurgical structure and pure crystal structure in order to have the best corrosion resistance.

Ni-Mo alloy Hastelloy B Mesh, the carbon and silicon content is extremely low, reducing the HAZ carbon and other impurities precipitation, so the weld has sufficient corrosion resistance. Alloy Hastelloy B Mesh in the reduction of medium with very good corrosion resistance, such as a various temperature and concentration of hydrochloric acid. In the middle of the concentration of sulfuric acid solution (or contain a certain amount of chloride ions) also has very good corrosion resistance. At the same time can be used to acetic acid and phosphoric acid environment. Alloy material suitable only in the metallurgical structure and pure crystal structure in order to have the best corrosion resistance.

Hastelloy B Mesh/Screen Applied field:

Alloy Hastelloy B Mesh with a wide range of applications in the field of chemical, petrochemical, energy manufacturing and pollution control , particularly in the sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, and other industries.

Alloy Hastelloy B Mesh with a wide range of applications in the field of chemical, petrochemical, energy manufacturing and pollution control , particularly in the sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid, and other industries.

Hastelloy B Mesh/Screen Chemical compostion:

Aolly | C | Mn | Si | P | S | Cr | Ni | Mo | Fe |

Hastelloy B Mesh | ≤0.05 | ≤1.00 | ≤1.00 | ≤0.030 | ≤0.030 | ≤1.00 | 58.0 ~64.0 | 26.0 ~30.0 | 4.0 ~6.0 |

Hastelloy B Mesh/Screen Physical properties:

Density | 9.24g/cm3 |

Melting point | 1330-1380℃ |

Hastelloy B Mesh Alloy minimum mechanical properties in the room temperature:

Alloy state | Tensile strength Rm N/mm2 | Yield strength RP0.2N/mm2 | Elongation A5 % |

Hastelloy B Mesh | 690 | 310 | 40 |

Mesh Weaving Method

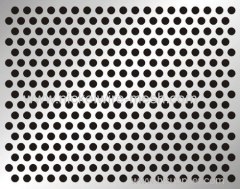

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |

The Service Part has more information about mesh form.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!