You are here: home > Learning Gallery > How Many Nickel and Nickel Alloys Do You Know?--1

Product (738)

- Pure Nickel Products (38)

- Incoloy Products (74)

- Inconel Products (72)

-

FeCrAl Product

(99)

-

Nichrome Products

(68)

- Monel Products (36)

- Hastelloy Products (49)

- Nickel Iron Alloy Product (59)

-

Nickel Copper alloys

(47)

- Nonferrous Metal Product (27)

-

Resistance Wire

(90)

- Stainless Steel Product (42)

- Mesh Demister (20)

- Others (17)

Product Forms (14)

Quality Certificate (11)

Learning Gallery (30)

Incoloy News (9)

Inconel News (22)

Molybdenum News (7)

Nikrothal News (4)

Nichrome News (13)

Titanium News (2)

Nickel News (8)

Alloys House (30)

Tools (27)

Nickel alloy News (30)

Latest Buzz (30)

nickel chrome copper iron alloys news (28)

Credit Report

Products Index

Company Info

Heanjia Super-metals Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Beijing

Province/State: Beijing

Country/Region: China (Mainland)

Learning Gallery

How Many Nickel and Nickel Alloys Do You Know?--1

Nickel and Nickel Alloys

Nickel has been used in alloys that date back to the dawn of civilization. Chemical analysis of artifacts has shown that weapons, tools, and coins contain nickel in varying amounts.

Nickel in elemental form or alloyed with other metals and materials has made significant contributions to our present-day society and promises to continue to supply materials for an even more demanding future.

Nickel is a versatile element and will alloy with most metals. Complete solid solubility exists between nickel and copper. Wide solubility ranges between iron, chromium, and nickel make possible many alloy combinations.

Applications and Characteristics of Nickel Alloys

Nickel and nickel alloys are used for a wide variety of applications, the majority of which involve corrosion resistance and/or heat resistance. Some of these include:

·Aircraft gas turbines

·Steam turbine power plants

·Medical applications

·Nuclear power systems

·Chemical and petrochemical industries

A number of other applications for nickel alloys involve the unique physical properties of special-purpose nickel-base or high-nickel alloys. These include:

·Low-expansion alloys

·Electrical resistance alloys

·Soft magnetic alloys

·Shape memory alloys

Heat-Resistant Applications

Nickel-base alloys are used in many applications where they are subjected to harsh environments at high temperatures. Nickel-chromium alloys or alloys that contain more than about 15% Cr are used to provide both oxidation and carburization resistance at temperatures exceeding 760°C.

Corrosion Resistance

Nickel-base alloys offer excellent corrosion resistance to a wide range of corrosive media. However, as with all types of corrosion, many factors influence the rate of attack. The corrosive media itself is the most important factor governing corrosion of a particular metal.

Low-Expansion Alloys

Nickel was found to have a profound effect on the thermal expansion of iron. Alloys can be designed to have a very low thermal expansion or display uniform and predictable expansion over certain temperature ranges.

Iron-36% Ni alloy (Invar) has the lowest expansion of the Fe-Ni alloys and maintains nearly constant dimensions during normal variations in atmospheric temperature.

The addition of cobalt to the nickel-iron matrix produces alloys with a low coefficient of expansion, a constant modulus of elasticity, and high strength.

Electrical Resistance Alloys

Several alloy systems based on nickel or containing high nickel contents are used in instruments and control equipment to measure and regulate electrical characteristics (resistance alloys) or used in furnaces and appliances to generate heat (heating alloys).

Types of resistance alloys containing nickel include:

·Cu-Ni alloys containing 2 to 45% Ni

·Ni-Cr-Al alloys containing 35 to 95% Ni

·Ni-Cr-Fe alloys containing 35 to 60% Ni

·Ni-Cr-Si alloys containing 70 to 80% Ni

Types of resistance heating alloys containing nickel include:

·Ni-Cr alloys containing 65 to 80% Ni with 1.5% Si

·Ni-Cr-Fe alloys containing 35 to 70% Ni with 1.5% Si + l% Nb

Soft Magnetic Alloys

Two broad classes of magnetically soft materials have been developed in the Fe-Ni system. The high-nickel alloys (about 79% Ni with 4 to 5% Mo; bal Fe) have high initial permeability and low saturation induction.

Shape Memory Alloys

Metallic materials that demonstrate the ability to return to their previously defined shape when subjected to the appropriate heating schedule are referred to as shape memory alloys. Nickel-titanium alloys (50Ni-50Ti) are one of the few commercially important shape memory alloys.

Commercial Nickel and Nickel Alloys

The commercial forms of nickel and nickel-base alloys are fully austenitic and are used/selected mainly for their resistance to high temperature and aqueous corrosion.

Commercially Pure and Low-Alloy Nickels

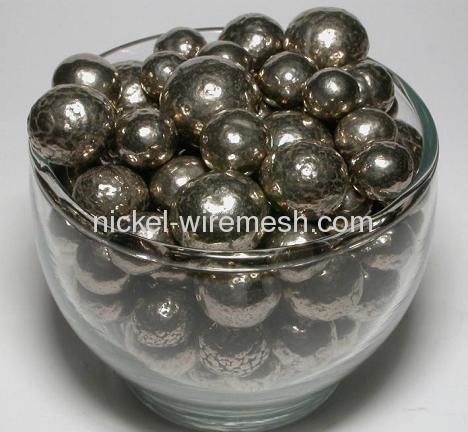

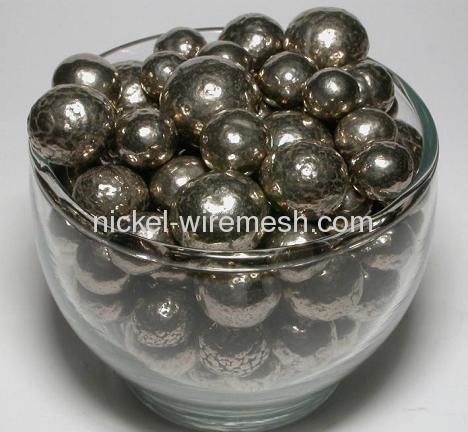

Nickel is supplied to the producers of nickel alloys in powder, pellets, or anode forms. This has led to a whole series of alloy modifications, with controlled compositions having nickel contents ranging from about 94% to virtually 100%.

These materials are characterized by high density, offering magnetic and electronic property capabilities. They also offer excellent corrosion resistance to reducing environments, along with reasonable thermal transfer characteristics. Some nickels of commercial importance include:

Nickel 200, Nickel 201, Nickel 205, Nickel 270 and 290, Permanickel Alloy 300, Duranickel Alloy 301.

Nickel-copper alloys have been found to possess excellent corrosion resistance in reducing chemical environments and in sea water, where they deliver excellent service in nuclear submarines and various surface vessels. By changing the various proportions of nickel and copper in the alloy, a whole series of alloys with different electrical resistivities and Curie points can be created. Some nickel-copper alloys of commercial importance include:

Alloy 400 (66% Ni, 33% Cu), Alloy R-405, Alloy K-500.

The nickel-chromium and nickel-chromium-iron series of alloys led the way to higher strength and resistance to elevated temperatures. Today they also form the basis for both commercial and military power systems. Two ofthe earliest developed Ni-Cr and Ni-Cr-Fe alloys were:

·Alloy 600 (76Ni-15Cr-8Fe).

·Nimonic alloys (80Ni-20Cr + Ti/Al).

Some high-temperature variants include:

·Alloy 601. Lower nickel (61%) content with aluminum and silicon additions for improved oxidation and nitriding resistance

·Alloy X750. Aluminum and titanium additions for age hardening

·Alloy 718. Titanium and niobium additions to overcome strainage cracking problems during welding and weld repair

·Alloy X (48Ni-22Cr-18Fe-9Mo + W). High-temperature flat-rolled product for aerospace applications

·Waspaloy (60Ni-19Cr-4Mo-3Ti-1.3Al). Proprietary alloy for jet engine applications

Some corrosion-resistant variants in the Ni-Cr-Fe system include:

·Alloy 625. The addition of 9% Mo plus 3% Nb offers both high-temperature and wet corrosion resistance; resists pitting and crevice corrosion

·Alloy G3/G30 (Ni-22Cr-19Fe-7Mo-2Cu). The increased molybdenum content in these alloys offers improved pitting and crevice corrosion resistance

·Alloy C-22 (Ni-22Cr-6Fe-14Mo-4W). Superior corrosion resistance in oxidizing acid chlorides, wet chlorine, and other severe corrosive environments

·Alloy C-276 (17% Mo plus 3.7W). Good seawater corrosion resistance and excellent pitting and crevice corrosion resistance

·Alloy 690 (27% Cr addition). Excellent oxidation and nitric acid resistance; specified for nuclear waste disposal by the vitreous encapsulation method

Pre Page:

Rene 41

Next Page:

How Many Nickel and Nickel Alloys Do You...